When investigating the mechanism behind energy storage in coupled inductors, it is clear that this phenomenon is rooted in a number of intricate principles. 1. Coupling between inductors plays a pivotal role in enabling energy transfer through mutual inductance, allowing energy to be stored across both inductors. 2. Core material influences performance, as varied materials provide different efficiencies in storing and releasing energy. 3. Operating frequency is crucial, since it impacts the amount of energy that can be stored during each cycle. 4. Circuit configuration determines energy dynamics, with distinct designs leading to diverse storage capabilities and efficiency levels.

When examining these dimensions, we delve into the underlying principles of magnetism, circuit design, and material science to gain insights into energy storage functions. For instance, the magnetic coupling between devices translates to substantial energy conservation during operational cycles. Through this exploration, a nuanced understanding emerges, highlighting the multifaceted nature of coupled inductors and their crucial roles in modern electronics.

1. UNDERSTANDING COUPLED INDUCTORS

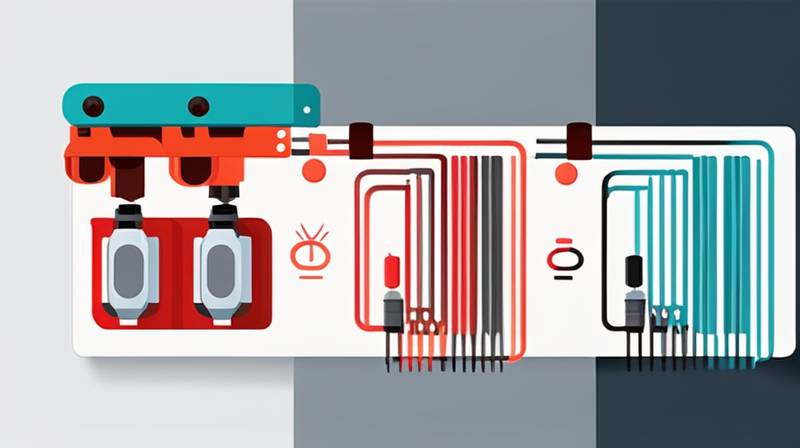

The foundation of coupled inductors can be traced back to the principles of electromagnetic induction. These devices consist of two or more inductors that are magnetically linked, enabling them to share energy efficiently. Their primary function lies in storing energy in a magnetic field when electrical current flows through them, creating a dynamic relationship between them.

When one inductor, say L1, carries an electric current, it generates a magnetic field that can induce a voltage in another inductor, L2, situated close by. This interdependence illustrates the critical concept of mutual inductance, whereby the inductance of one coil impacts the overall inductance of the system. Consequently, this coupling signifies a fundamental energy storage mechanism, as energy can be transferred between inductors while maintaining optimized efficiency—a notable advantage in various applications.

2. MECHANISMS OF ENERGY STORAGE

In terms of energy storage mechanisms, the operation of coupled inductors predominantly relies on their ability to establish magnetic fields. As current flows through the coils, the magnetic field generated can be quantified using Faraday’s law of induction, which states that the induced electromotive force (emf) in any closed circuit is equal to the rate of change of the magnetic flux through that circuit. This principle underscores the relationship between the current, magnetic field, and the eventual energy that can be stored.

The energy stored in each inductor can be expressed mathematically using the formula (E = \frac{1}{2}Li^2), where (E) represents energy, (L) signifies inductance, and (i) denotes current. This relationship highlights that the inductance value plays a significant role in determining energy storage capacity. When coupled inductors are designed, manipulating their dimensions and core materials enhances inductance, leading to more efficient energy retention and transfer.

3. CORE MATERIAL EFFECTS

The core material employed in coupled inductors has a profound impact on their overall performance. Magnetic cores come in various materials, such as ferrite and laminated silicon steel, each offering different magnetic properties. For example, ferrite materials are often favored due to their high magnetic permeability, which enhances the strength of the magnetic field and reduces energy losses through eddy currents.

Moreover, the design of the core contributes to the extent of energy retention capacity. Cores with optimized geometries enable better flux linkage between inductors, which translates to higher mutual inductance values. This means that through advancements in materials science and engineering, manufacturers can tailor core materials to maximize efficiency in energy storage applications. Such precision often results in compact designs that yield lighter and more efficient coupled inductors, enhancing the practicality in real-world applications.

4. IMPACT OF OPERATING FREQUENCY

Operating frequency plays a pivotal role in the energy storage capabilities of coupled inductors. As frequency increases, the rate at which the inductor alternates between storing and releasing energy escalates, directly influencing the overall efficiency of the circuit. In high-frequency applications such as switch-mode power supplies, the ability of a coupled inductor to operate efficiently at elevated frequencies ensures that energy is effectively stored and delivered to end-use components.

However, increased frequency can lead to challenges such as core losses and skin effect, which must be carefully managed. Core losses consist of hysteresis and eddy current losses, both of which can contribute to diminished energy storage capability. By selecting cores with lower losses and designing inductors that accommodate increased frequency demands, engineers can capitalize on the advantages offered by coupled inductors in high-performance energy storage applications.

5. CIRCUIT CONFIGURATIONS

Different circuit configurations significantly affect how coupled inductors store and release energy. Configurations such as series, parallel, and transformer-like topologies allow for adaptable energy management based on the intended application. In a series configuration, the total inductance increases, amplifying energy storage capacity. Conversely, a parallel configuration might be better suited for applications emphasizing current capacity and flexibility in energy distribution.

Transformers utilize coupled inductors innovatively to step up or step down voltages while maintaining energy balance across circuits. Each configuration serves unique application needs, aligning with operational goals while emphasizing the roles of inductors in energy conservation and transfer. Therefore, understanding circuit designs enables engineers to leverage coupled inductors effectively based on specific project requirements.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MAIN ADVANTAGES OF COUPLED INDUCTORS?

Coupled inductors present several advantages that make them valuable in numerous applications. 1. Enhanced energy transfer efficiency is a primary benefit, as magnetic coupling allows for effective energy sharing between inductors. This efficiency not only minimizes energy losses but also supports higher power densities compared to single inductors.

2. Flexibility in circuit design emerges as another significant advantage. The inherent design of coupled inductors allows them to be integrated into a variety of systems, providing the ability to achieve desired inductance values through magnetic coupling. This versatility aids in the design of more compact and efficient circuits.

Moreover, 3. Cost-effectiveness results from improved performance metrics, as coupled inductors can lead to lower component counts in circuit designs, reducing overall costs while maintaining operational effectiveness. These advantages establish coupled inductors as vital components in energy systems ranging from power supplies to renewable energy applications.

HOW DOES MAPPING PARAMETERS IMPACT PERFORMANCE?

Mapping parameters such as inductance, current ratings, and core material choices has substantial implications for the performance of coupled inductors. 1. Inductance values determine energy storage capacity, which can directly influence how effectively a circuit functions under various loads. By accurately mapping inductance values, engineers can optimize coupled inductor designs for specific scenarios, ensuring that energy is retained and transferred in alignment with application demands.

2. Current ratings signify operational limits for coupled inductors. Higher current ratings indicate a greater ability to handle electrical load without overheating or sustaining damage, thus extending the lifespan of the components. Additionally, core material mappings assist in evaluating how different materials respond to changing frequencies and magnetic fields, leading to improved designs that minimize losses and enhance overall energy efficiency.

WHAT ARE THE LIMITATIONS OF COUPLED INDUCTORS?

While coupled inductors offer numerous benefits, they also present certain limitations. 1. Size and weight constraints can restrict their use in applications where space is at a premium. Larger core designs that maximize energy transfer often lead to bulkier inductive components, posing challenges in compact electronics where integration of various components is crucial.

2. Thermal management remains another concern, especially in high-frequency operations where losses can lead to increased temperatures. Managing these heat levels presents a challenge that must be addressed through strategic designs and appropriate cooling mechanisms.

Additionally, the complexity of designing efficient coupled inductor systems can deter some applications, requiring advanced knowledge of electromagnetic principles and circuit design. Therefore, while coupled inductors are invaluable in modern electronics, understanding their limitations is essential for effective application.

Analyzing the multifaceted nature of coupled inductors reveals intricate mechanisms that contribute to their role in energy storage. The interplay of magnetic coupling, material choices, operating frequencies, and designs illustrates the sophisticated dynamics involved. By recognizing the significance of these elements, practitioners in the electronics field can harness the potential of coupled inductors, thereby enhancing overall system efficiency and performance. Their design flexibility supports a wide range of applications, from power converters to renewable energy solutions, showcasing their relevance in contemporary technological advancements. Therefore, coupled inductors stand as pivotal components, reflecting the importance of engineering and material science collaboration in crafting efficient energy management solutions for the future. Moreover, addressing the potential challenges while striving for improvements in this area promises continued innovation and adaptation to evolving needs, thereby solidifying the role of coupled inductors in driving technological progress.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-coupled-inductor-store-energy/