1. Signs of Pressure Release, 2. Visual Inspection, 3. Abnormal Sounds, 4. Proximity to Equipment

Identifying if a solar tube has exploded involves careful attention to several definitive indicators. 1. Signs of Pressure Release: If there is a sudden release of pressure, accompanied by a hissing sound or immediate change in atmospheric conditions, it could indicate that the solar tube has ruptured. Such occurrences can lead to the dispersion of contained fluids or gases, which indicate structural failure. 2. Visual Inspection: An inspection of the tube’s surface for cracks, bulges, or shattered glass can present clear evidence of failure. 3. Abnormal Sounds: Listen for unusual noises that deviate from the normal operational hum of the system. Explosive ruptures often produce sharp, loud sounds. 4. Proximity to Equipment: Monitoring the area around the solar tube can reveal secondary effects, such as damage to electrical components or other nearby installations, indicating a potential explosion.

Engaging in a detailed inspection following these signs is crucial for ensuring safety and maintaining system functionality.

1. SIGNS OF PRESSURE RELEASE

When assessing the integrity of a solar tube, the release of pressure stands out as a critical indicator of potential explosion. This can manifest suddenly and without warning, often leading to an immediate atmospheric change. The hissing sound commonly associated with escaping gases or fluids signifies a rupture, resulting from an internal buildup of pressure that exceeds the structural limits of the tube.

The significance of pressure release cannot be overstated. When solar tubes operate, they are subject to considerable temperature fluctuations, which can cause rapid expansion and contraction of the gaseous contents. This dynamic creates variances in pressure; if the pressure surpasses what the design specifications allow, a rupture occurs. This sudden event not only endangers the functionality of the solar collector but also poses safety risks to individuals nearby. Therefore, recognizing the sound associated with pressure release is crucial in early detection.

Further examination of the system following a pressure release is essential. Monitoring factors such as temperature fluctuations and checking safety relief valves can aid in pinpointing the origin and reason for the failure. An immediate response to pressure anomalies includes shutting down adjacent systems to prevent cascading failures or additional hazards. This proactive behavior is crucial for maintaining safety and system integrity.

2. VISUAL INSPECTION

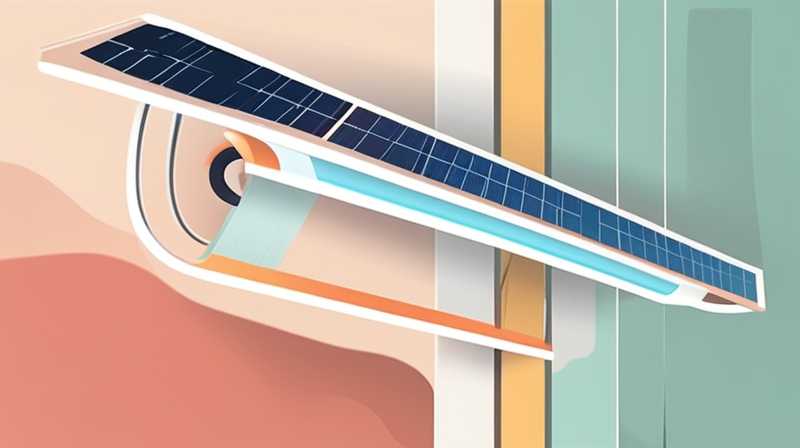

Conducting a thorough visual inspection of the solar tube is essential in identifying potential ruptures or weaknesses. One of the key visual cues to observe is the presence of cracks or fractures on the outer surface. These indicators might initially appear as fine lines or intricate spider-web patterns but can signify a significant weakening of the tube’s structural integrity. If these signs are evident, it becomes imperative to address the issue before any further operation takes place.

In particular, bulging or warping of the solar tube indicates that internal pressures are shifting, potentially leading to failure. This deformation can emerge over time due to various factors such as temperature fluctuations, material degradation, or manufacturing defects. When experiencing such distortions, immediate consideration for replacement or repair becomes necessary.

Furthermore, collecting data regarding the historical performance of the solar tubes enhances the effectiveness of the inspection. Keeping detailed records of previous maintenance activities, repairs, and any changes in performance metrics allows for more accurate diagnostics during a visual inspection. By comparing any anomalies with these historical records, it becomes significantly easier to determine whether the current state of the tube warrants the need for immediate intervention or if the observed symptoms are consistent with general wear and tear that may not necessarily indicate failure.

3. ABNORMAL SOUNDS

Unusual sounds emanating from a solar tube system can be critical indicators of malfunction or potential explosive failure. The acoustic signature accompanying a ruptured tube often differs significantly from the normal operational sounds, which typically involve a consistent hum generated by the system’s components. When abnormal noises manifest, identifying and diagnosing these sounds promptly is crucial.

Potential sources of concerning noises include sharp cracks, popping sounds, or continuous hissing. For instance, sharp cracking noises could indicate that the structural integrity of the tube has been compromised, resulting in tensions being released suddenly. On the other hand, continuous hissing could suggest that gas or fluid is escaping from a breach, posing not only a threat to the efficiency of the solar energy system but also to those nearby.

Observing patterns in sound can provide additional insights into the type and extent of the problem. For instance, if sounds intensify under specific conditions, such as during sudden temperature increases or after a system overhaul, these elements must be considered carefully. Investing in sound monitoring technology can be beneficial, as it enhances the ability to track sound patterns and detect irregularities, creating a more comprehensive understanding of the system’s health.

4. PROXIMITY TO EQUIPMENT

Understanding the geographic context of solar tubes is vital for determining the likelihood of explosion impacts. Proximity to electrical components or other critical infrastructure can exacerbate the dangers associated with a failure. When a solar tube explodes, the resultant shrapnel and debris can lead to subsequent damage or secondary explosions, making awareness of surrounding equipment and systems crucial.

Another critical aspect is the potential for fire hazards. Solar tubes contain materials that, when released into the environment, can be flammable. Therefore, if a break occurs near electrical systems or other heat-generating apparatus, this raises the potential for additional catastrophes. Conducting risk assessments that consider these proximity factors allows for better safety planning and system designs that mitigate such risks.

Regular assessments of nearby equipment are vital, as they inform maintenance schedules and help to categorize the vulnerability of auxiliary systems to explosions. By adopting rigorous inspection protocols and evaluating risk factors surrounding the solar tube, operators can both enhance safety measures and develop preventative strategies to manage potential failures.

FREQUENTLY ASKED QUESTIONS

WHAT SHOULD I DO IF I SUSPECT A SOLAR TUBE HAS EXPLODED?

In the event that you suspect an explosion involving a solar tube, immediate actions are essential for ensuring safety and minimizing harm. First, it is crucial to evacuate the area immediately to prevent exposure to potentially hazardous materials or high-pressure elements. After ensuring personal safety, contact emergency services to report the situation and seek professional assistance for evaluating the hazard.

Subsequently, avoid approaching the site until authorities have confirmed that it is safe. Once professionals are on the scene, they can assess the situation, document any evidence of failure, and implement necessary measures to mitigate risks. If possible, document the event from a safe distance, noting time and any observable signs of disruption, such as debris or unusual sounds. This information can be valuable for both safety assessments and for determining the steps required for subsequent investigation and repairs.

HOW CAN I PREVENT SOLAR TUBE EXPLOSION IN THE FUTURE?

Preventing future incidents involving solar tube explosions necessitates a multifaceted approach centered around ongoing maintenance, vigilant monitoring, and strategic design modifications. Regular inspections should be carried out by qualified technicians to assess structural integrity, analyze materials for wear and tear, and detect early signs of pressure anomalies or thermal fluctuations.

Furthermore, implementing advanced monitoring systems can provide real-time data on operational conditions, enabling proactive measures to govern potential risks. Technologies such as pressure sensors and thermal cameras can identify deviations from standard operating parameters, allowing for immediate corrective actions before serious incidents occur.

Educating personnel on the appropriate operational protocols likewise contributes to risk mitigation. Training staff to recognize warning signs and maintain equipment diligently fosters an environment focused on safety and performance. By employing a comprehensive strategy combining proactive inspections, enhanced monitoring, and educational initiatives, significant strides can be made toward preventing future explosions and ensuring the longevity of the solar energy system.

WHAT ARE THE COMMON CAUSES OF SOLAR TUBE EXPLOSIONS?

Understanding the common causes behind solar tube explosions aids in developing strategies to mitigate risk. Excessive pressure buildup stands out as a primary factor, often resulting from overheating or malfunctioning pressure relief mechanisms that fail to accommodate increased thermal expansion. Regular maintenance of these systems ensures proper functioning and identifies any potential weaknesses in design.

Inadequate material selection or manufacturing defects can also lead to weaknesses that predispose a solar tube to failure. Utilizing high-quality materials that can withstand environmental stressors is crucial for longevity and reliability. Regularly assessing the quality of materials and ensuring compliance with industry standards helps to prevent future incidents.

Additionally, environmental factors such as exposure to extreme weather conditions or corrosive substances can further exacerbate vulnerabilities. By recognizing these risks and implementing preventative measures, stakeholders can significantly reduce the likelihood of catastrophic failures.

ENDING REMARKS

The identification of potential solar tube explosions is a critical component of effective energy management and safety protocols. Recognizing signs such as pressure release, engaging in thorough visual inspections, and paying careful attention to abnormal sounds constitutes a comprehensive assessment strategy. Furthermore, awareness of proximity to surrounding equipment and implementing robust prevention measures can significantly reduce the risk of future incidents. Rigorous ongoing training and a commitment to quality materials are equally essential components in maintaining system integrity. Stakeholders must prioritize meticulous monitoring and maintenance practices to harness the efficiency of solar technology while ensuring safety. In the evolving landscape of renewable energy, adopting a proactive approach to identifying and addressing potential failures will ultimately lead to more reliable systems, increased safety, and enhanced public confidence in solar technologies.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-you-know-if-the-solar-tube-exploded/