How do industrial enterprises carry out energy storage projects?

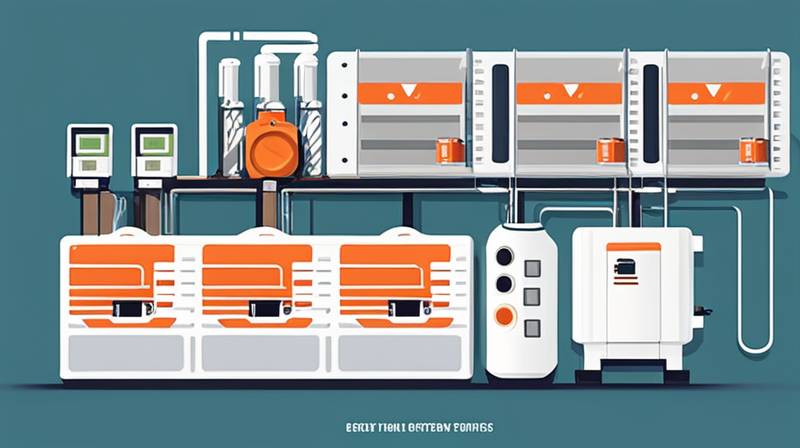

1. Industrial enterprises carry out energy storage projects through comprehensive methodology, including: 1) thorough assessment of energy demands, 2) selection of appropriate storage technology, 3) integration with existing systems, and 4) evaluating economic viability. A detailed examination of energy requirements allows for the identification of suitable storage solutions that align with operational goals. For instance, technologies such as lithium-ion batteries, pumped hydro storage, and flywheels each offer distinct advantages based on specific use cases. Furthermore, to ensure seamless integration, enterprises often conduct pilot projects or simulations to minimize risks associated with implementation. Finally, economic feasibility analysis helps determine potential returns on investment, ensuring that energy storage aligns with the overall strategic goals of the organization.

1. ENERGY DEMAND ASSESSMENT

Examining energy needs constitutes a primary step in executing energy storage projects within industrial contexts. Organizations must conduct meticulous evaluations of their current and projected energy consumption patterns to establish foundational data. This process includes analyzing historical usage trends, peak demand periods, and operational schedules. A profound understanding of these factors enables enterprises to anticipate shifts in energy requirements driven by production changes, operational expansions, or market fluctuations.

A distinct aspect of evaluating energy demand is recognizing the differences between baseload and peak load requirements. Baseload energy, which represents consistent minimum energy consumption, differs significantly from peak load, the maximum energy demand occurring during specified intervals. By gaining insights into these dual categories, enterprises can select tailored energy storage systems that effectively bridge the gap between supply and demand fluctuations. Additionally, implementing advanced analytical tools can enhance forecasting accuracy, allowing organizations to fine-tune their energy management strategies.

2. SELECTION OF STORAGE TECHNOLOGIES

Upon completing the assessment of energy demand, enterprises must deliberate over the spectrum of available energy storage technologies. Diverse options exist, each tailored to unique operational needs and energy profiles. Lithium-ion batteries are noteworthy for their high energy density and rapid response times, making them ideal for applications requiring quick discharge capabilities. Conversely, pumped hydro storage capitalizes on gravitational potential energy and is well-suited for large-scale deployments across regions with suitable elevation changes.

Moreover, the choice of technology can be influenced by an organization’s sustainability goals. As industries pivot towards greener practices, storage solutions such as flow batteries and compressed air energy storage are increasingly favored due to their lower environmental impacts. Evaluating criteria such as lifespan, efficiency, maintenance requirements, and associated costs plays an instrumental role in determining the most advantageous technology for the enterprise.

3. INTEGRATION WITH EXISTING INFRASTRUCTURE

Subsequent to selecting suitable storage technologies, industrial enterprises grapple with the challenge of integrating these solutions into their current energy infrastructure. This phase necessitates rigorous planning and coordination among multiple stakeholders to align the energy system with technological advancements. Effective integration enables the smooth operation of energy storage alongside conventional energy generation sources, thus optimizing overall energy management.

It is essential to ascertain potential compatibility concerns that could arise during integration. Organizations often utilize simulation tools to anticipate challenges, validate system designs, and identify potential bottlenecks. Furthermore, configuring an energy management system can enhance oversight, enabling real-time monitoring of energy flows and automated decision-making processes that optimize storage utilization. When executed efficiently, integration not only bolsters reliability but also enhances energy efficiency—maximizing returns on investment.

4. EVALUATING ECONOMIC VIABILITY

The final consideration in the execution of energy storage projects involves assessing economic viability. This process requires organizations to carry out a comprehensive financial analysis that encompasses both upfront capital investments and ongoing operational costs. The goal is to ascertain positive returns on investment that align with the enterprise’s financial performance metrics and overall strategic objectives.

A multifaceted approach benefits this evaluation, incorporating various financial models such as Net Present Value (NPV), Internal Rate of Return (IRR), and Payback Period analysis. By leveraging diverse metrics, organizations can comprehend the long-term financial implications of investing in energy storage solutions. Additionally, assessing external factors such as regulatory support, incentives, and market dynamics is crucial in understanding the broader economic landscape that influences energy storage decisions.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE TECHNOLOGIES ARE COMMONLY USED IN INDUSTRIAL SETTINGS?

In the realm of industrial enterprises, various energy storage technologies are employed, each with its distinct advantages and applications. Commonly utilized systems include lithium-ion batteries, known for their efficiency and quick charge-discharge cycle, making them suitable for applications requiring rapid response to energy fluctuations. Furthermore, pumped hydro storage is extensively used for large-scale energy storage solutions, leveraging gravity to store energy in reservoirs.

Additionally, technologies such as compressed air energy storage and flow batteries have gained traction due to their suitability for large-volume storage needs and environmentally friendly operation, respectively. Each of these systems caters to specific energy demands and operational requirements, thereby offering industrial enterprises a diverse toolkit for energy management. Organizations must engage in a thorough evaluation of their unique energy consumption profiles to select the most appropriate technology that aligns with their operational goals.

HOW DOES ENERGY STORAGE IMPACT ENERGY COSTS FOR INDUSTRIAL ENTERPRISES?

Incorporating energy storage solutions can significantly impact energy costs for industrial enterprises by enabling strategic energy management practices. Energy arbitrage, wherein organizations purchase electricity during low-demand periods and utilize stored energy during peak pricing times, is one of the prominent financial benefits of energy storage. This approach helps to stabilize energy spending and mitigate costs associated with fluctuations in energy prices throughout the day.

Moreover, energy storage enhances the efficiency of renewable energy sources, such as solar and wind, by storing excess energy generated during peak production times for later use. This capability furthers the reliance on renewables, reducing dependency on costly fossil fuel generation and volatile energy markets. Consequently, organizations can establish a more predictable and cost-effective energy sourcing strategy that aligns with their broader sustainability and financial goals.

WHAT ARE THE POTENTIAL CHALLENGES ASSOCIATED WITH IMPLEMENTING ENERGY STORAGE PROJECTS IN INDUSTRIES?

Implementing energy storage projects in industrial environments presents several potential challenges that organizations must navigate adeptly. One of the foremost hurdles is the high initial capital investment associated with acquiring suitable storage technologies. Accurately estimating potential return on investment can be complex, leading to hesitancy in capital allocation.

Additionally, integration difficulties can arise, particularly in older facilities with pre-existing energy infrastructure. Organizations might face compatibility issues or operational disruptions during the integration phase. Further complexities may stem from regulatory challenges or evolving energy policies, which could impact project timelines and financial feasibility. Thus, thorough planning, risk assessment, and stakeholder engagement are crucial to mitigating these challenges, ensuring successful execution of energy storage projects.

The implementation of energy storage initiatives plays a pivotal role in the current industrial landscape. Industrial enterprises navigate a complex terrain characterized by evolving energy demands, technological advancements, and sustainability imperatives. To successfully embark on energy storage projects, organizations must meticulously assess their energy requirements, select suitable technologies, and optimize integration with existing systems while ensuring economic feasibility. Each facet of this methodology is paramount, as it lays the groundwork for a robust energy management strategy that maximizes operational efficiency and resilience.

Moreover, as industries increasingly embrace renewable energy sources, the strategic deployment of energy storage systems facilitates the transition towards sustainable practices. This trend not only aids in balancing demand and supply fluctuations but also enables organizations to take advantage of economically favorable energy pricing. The economic and environmental benefits of effectively harnessing energy storage cannot be overstated, as they contribute to significant long-term savings and reduced carbon footprints.

In navigating these intricate dynamics, leaders in industrial sectors must adopt a holistic approach that encompasses technical considerations, economic analysis, and strategic foresight. By doing so, they empower their enterprises to thrive amid a rapidly changing energy landscape while positioning themselves as proactive participants in the global shift toward sustainable energy solutions. As industrial enterprises continue to innovate and adapt, the integration of energy storage technology will undoubtedly shape the future, paving the way for a resilient and sustainable energy ecosystem.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-industrial-enterprises-carry-out-energy-storage-projects/