1. Energy storage systems significantly decrease operational costs for large industrial plants by optimizing energy usage, enhancing load management, and reducing peak demand charges. 2. These systems provide a means for facilities to manage their energy consumption more effectively, enabling them to take advantage of lower electricity rates during off-peak hours. 3. Additionally, storage solutions contribute to enhanced demand response capabilities, leading to further cost reductions. 4. The adoption of advanced energy storage technologies has been shown to drive down overall energy expenditures while simultaneously improving operational efficiency.

1. UNDERSTANDING ENERGY STORAGE SYSTEMS

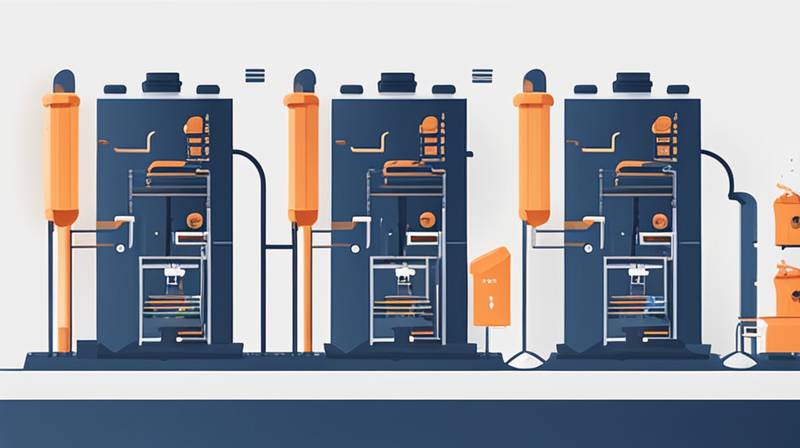

Energy storage systems (ESS) integrate various technologies designed to store energy for later use, making them vital assets for large industrial plants seeking to mitigate operational costs. Properly implemented ESS can significantly influence how a facility uses energy, offering advantages that extend beyond mere power supply. The growing importance of these systems becomes evident as industries increasingly embrace sustainable practices and seek solutions that promote cost-saving measures.

Large industrial facilities typically consume substantial quantities of energy, and the associated costs can be a significant burden on operational budgets. Energy storage systems serve as a buffer between energy supply and demand, allowing facilities to store energy during periods of low demand or when energy use is cheaper, subsequently discharging that energy when consumption peaks or prices rise. Consequently, companies can stabilize their energy expenses while ensuring that operational needs are adequately met.

2. OPTIMIZING ENERGY USAGE

Energy management strategies and their importance

One of the foremost benefits of employing energy storage systems lies in their ability to optimize energy usage. Such systems enable industries to employ tailored energy management strategies, orchestrating energy consumption according to operational requirements. By adjusting when and how electricity is used, companies can significantly lower their energy bills.

An effective energy management strategy encompasses various elements, including analyzing energy consumption patterns, identifying peak usage periods, and evaluating potential cost savings. By leveraging advanced data analytics, businesses can pinpoint efficiency opportunities, resulting in substantial financial gains. A well-structured energy management plan not only cuts costs but also enhances the overall productivity of the plant.

Load shifting and its ramifications

Load shifting involves modulating energy consumption away from peak demand periods toward times when electricity is cheaper. Energy storage systems facilitate this transition by storing excess energy generated during off-peak hours and releasing this stored energy during peak demand. This practice can lead to reduced operational costs by lowering demand charges imposed by utilities.

For instance, when a plant can shift its peak load to periods of lower tariffs, the overall costs associated with electricity consumption can be notably minimized. Furthermore, load shifting contributes to grid stability, which can fortify relationships with utility providers. Companies that actively pursue load-shifting strategies can enjoy improved operational performance while also playing an integral role in energy conservation efforts.

3. PEAK DEMAND CHARGES

Understanding peak demand charges

Utilities often impose peak demand charges based on the highest average utilization of energy within a specified period (usually 15 or 30 minutes). For large industrial plants, these charges can account for a significant portion of monthly electricity bills. The financial repercussions are pronounced, as higher peak usage translates to escalated costs that have little to do with actual energy consumed.

Energy storage technologies effectively alleviate peak demand charges by allowing facilities to draw from stored energy when necessary, minimizing reliance on grid power during peak periods. Such strategies also facilitate a more predictable monthly energy expenditure. By carefully managing peak demands, industrial operators can effectively circumscribe their operational costs.

Cost-reduction strategies involving peak shaving

Peak shaving is another technique that integrates energy storage solutions to decrease charges associated with elevated demand levels. By storing energy during periods of low demand and discharging it during peak usage, businesses can shave off their peak demand and, consequently, their costs. This practice proves invaluable in managing operational expenses, particularly for facilities that experience significant fluctuations in energy use.

The implications of effective peak shaving are undeniable. Facilities reducing their peak demand can reinvest the savings back into operations, supporting growth initiatives or enhancing production capabilities. Furthermore, companies engaging in peak shaving initiatives often strengthen their competitive position within the market, making them better equipped to respond to evolving customer needs.

4. ENHANCED DEMAND RESPONSE CAPABILITIES

The role of demand response in energy savings

Demand response (DR) programs enable facilities to adjust their energy consumption in response to utility signals, typically aligned with grid capacity. By participating in DR programs, industrial plants can lower operational costs and receive financial incentives for reduced energy consumption during peak periods. Energy storage systems play a pivotal role in these scenarios by acting as a resource that can quickly discharge electricity back into the grid.

These enhancements are particularly advantageous for facilities that have substantial energy requirements and flexible operational processes. The ability to step down energy use when called upon not only fosters a sense of reliability with utility providers but can also create substantial savings on energy costs. As industries become more adept at integrating DR strategies, the potential for financial savings amplifies.

Strategic partnerships with utilities

Developing strategic partnerships with utility companies can yield significant advantages for large industrial plants combatting high operational costs. Collaborative programs often enable plants to secure favorable rates and incentives for utilizing energy storage solutions. Moreover, such partnerships facilitate access to valuable data regarding energy trends, allowing facilities to adapt their strategies accordingly.

By embracing energy storage technologies and engaging with utility initiatives, businesses can cultivate a streamlined energy sourcing model. These partnerships substantially enhance the overall operational landscape, emphasizing sustainable practices and energy efficiency while dramatically lowering costs associated with electricity consumption.

5. CASE STUDIES AND EXAMPLES

Success stories in various industries

Numerous industries have already started reaping the benefits of implementing energy storage solutions, highlighting their potential in transforming operational costs. For example, large-scale manufacturers have adopted storage systems to buffer their energy usage. By deploying energy storage, these companies manage loads more efficiently, subsequently seeing a noticeable decline in their monthly energy expenditures.

Another notable example lies in the realm of data centers, which require constant power availability. Organizations have benefited from integrating storage systems, allowing them to leverage stored energy during peak demand times, thereby avoiding exorbitant costs while ensuring consistent service delivery. The cross-industry appeal of energy storage solutions is evident, with applications ranging from manufacturing to information technology.

Lessons learned from these implementations

The implementation of energy storage systems does not come without challenges. Lessons learned from specific projects underline the need for careful planning and consideration of financial commitments. Effective stakeholder engagement, thorough assessments of site-specific energy needs, and comprehensive evaluations of available technologies can help facilitate a smoother implementation process.

Furthermore, organizations learn that cultivating organizational buy-in can dramatically enhance project success rates. By fostering a culture that prioritizes energy efficiency, companies can motivate teams to become proactive participants in minimizing operational costs, maximizing productivity, and improving overall performance.

QUESTIONS AND ANSWERS

HOW DOES ENERGY STORAGE IMPACT OPERATING EXPENSES?

Energy storage systems fundamentally influence operating expenses by enabling facilities to optimize their energy consumption. By storing energy during off-peak hours when electricity prices are lower and discharging it during peak demand, industrial plants can significantly lower their electricity bills. Furthermore, these systems assist in reducing peak demand charges, as they allow businesses to manage their energy loads more effectively. This financial effect compounds, leading to more favorable operating cost scenarios over time.

Moreover, modern energy storage solutions offer advanced capabilities that include analytics to predict energy usage patterns and adjust accordingly. These insights empower facilities to fine-tune their operations for maximum cost efficiency. Therefore, energy storage not only reduces energy-related expenses but also fosters a culture of operational efficiency that can lead to sustained financial gains.

WHAT ARE THE LONG-TERM BENEFITS OF ENERGY STORAGE SYSTEMS?

The long-term benefits of incorporating energy storage systems extend beyond immediate cost savings. Over time, organizations can expect reduced overall operational costs, enhanced energy reliability, and improved sustainability metrics. As energy markets evolve, and with an increasing emphasis on renewable energy sources, facilities leveraging energy storage can better integrate intermittent renewables, sustaining a stable operational energy supply.

In addition to financial savings, companies experience gains in competitiveness due to lower energy costs. They can redirect savings into other essential operational areas, promoting growth and innovation. Furthermore, as environmental standards become more stringent, adopting energy storage solutions enables organizations to align with regulatory expectations while contributing to carbon footprint reduction.

WHAT ARE THE CHALLENGES IN IMPLEMENTING ENERGY STORAGE SYSTEMS?

While the adoption of energy storage systems presents numerous advantages, several challenges can arise during implementation. Initial capital investment can be substantial, and companies must determine the feasibility of financing options. Organizations must also navigate regulatory frameworks and utility policies that influence the effectiveness of energy storage technologies.

Another significant challenge is the integration of storage systems into existing operational infrastructures. Developing a cohesive energy management strategy requires thorough analysis and careful planning. Facility operators must also engage employees and foster a culture oriented toward energy efficiency. While challenges exist, thoughtful planning can mitigate these issues and result in successful implementations.

EMBRACING ENERGY STORAGE FOR SUSTAINABLE FINANCIAL IMPROVEMENTS

The adoption of energy storage technologies is no longer a mere consideration but an essential strategy for enhancing the financial landscape of large industrial plants. Integrating these systems into operational frameworks not only facilitates optimized energy consumption and peak demand management but also leads to remarkable cost savings over time. The financial implications are far-reaching, encompassing reduced monthly energy bills, lowered peak demand charges, and improved operational efficiency. Through advanced data analytics, companies can predict usage patterns and adjust accordingly to leverage lower energy rates effectively. The operational insights gained through energy storage can drive a culture of efficiency, allowing organizations to harness available resources more effectively. As energy regulations tighten and sustainability becomes integral to operational strategy, energy storage systems provide a viable means to meet modern energy needs. Beyond immediate financial gains, businesses that embrace energy storage solutions are better positioned for long-term success and competitiveness. Investing in these technologies lays the groundwork for a more sustainable, efficient, and economically viable operational future. As industries continue to evolve, the relevance of energy storage will only grow, reinforcing its pivotal role in shaping contemporary industrial landscapes for the better.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-energy-storage-systems-reduce-operational-costs-for-large-industrial-plants/