How about the sheet metal shell of energy storage battery

1. The sheet metal shell serves a critical role in energy storage batteries: 2. It provides structural integrity and protection to internal components, 3. Enhances thermal management through proper heat dissipation, 4. Contributes to the overall safety and longevity of the battery system.

The sheet metal shell of energy storage batteries is more than just an outer covering; it is a fundamental element that impacts the battery’s performance, safety, and durability. Sheet metal materials, often aluminum or stainless steel, are selected not only for their strength but also for their weight and corrosion resistance. This protective case holds the critical internal components securely while enhancing the overall effectiveness of the energy storage system. In this exploration, various aspects surrounding the sheet metal shell, including its design, function, and impact on safety and performance, will be unveiled.

1. FUNCTIONALITY OF SHEET METAL SHELLS

The sheet metal shell serves multiple functions crucial to the operation of energy storage batteries. First and foremost, it provides structural integrity. This means maintaining the shape and compactness of the battery pack, which is essential for efficient energy storage and retrieval processes. An effective design prevents deformation due to thermal expansion and external pressures, allowing batteries to operate at their optimal capacity without performance degradation over time.

In addition to structural integrity, the shell acts as a barrier against environmental factors. It safeguards the internal mechanisms from moisture, dust, and other contaminants. Many battery types, such as lithium-ion batteries, are sensitive to water and particulate matter, which can lead to chemical reactions that compromise battery performance. A durable shell provides peace of mind by minimizing the risk of external damage, thus ensuring the safe operation of the device.

Moreover, the material used plays a pivotal role in the thermodynamic properties of the battery system. By utilizing materials with high thermal conductivity, the shell can facilitate effective heat dissipation. Batteries generate heat during charging and discharging cycles; without an effective heat management strategy, the risk of thermal runaway increases, potentially leading to catastrophic failures. The metal shell dissipates heat away, maintaining a stable operating temperature within the battery, which is essential for extending its lifespan.

2. SAFETY CONSIDERATIONS

Safety is a paramount concern in energy storage applications. The sheet metal shell contributes significantly to the overall safety of the battery system. Chemically reactive substances such as lithium can pose dangers if not contained properly. The robust construction of the shell ensures that even in the event of physical damage or internal short-circuiting, the risk of leakage or explosion is significantly mitigated. This containment is critical not only for product reliability but also for protecting end-users and the environment.

Furthermore, the shell can be engineered with safety mechanisms such as pressure relief vents. This design feature aids in managing internal pressures that may build up during operation. In situations where gas is generated due to chemical reactions, these vents allow for safe release, preventing explosive failures and ensuring user safety. Therefore, a metal shell is intrinsic to developing safer batteries that can withstand extreme conditions.

Additionally, innovations in sheet metal technology are continually enhancing the safety profiles of battery systems. New coatings and treatments can be applied to provide additional resistance to corrosion and heat. Such advancements can drastically improve battery longevity and reliability, which is critical for applications ranging from consumer electronics to electric vehicles.

3. MANUFACTURING AND SUSTAINABILITY

The manufacturing processes involved in creating sheet metal shells for energy storage batteries are vital from both an economic and environmental standpoint. The industry is moving towards more sustainable practices, reducing waste, and promoting recycling. Using lightweight, recyclable materials not only decreases the environmental impact but also enhances the performance of the battery. A lighter shell can lead to reductions in energy consumption during transport and use, thereby improving the battery system’s overall efficiency.

Moreover, advances in manufacturing technologies, such as laser cutting and automated welding, are revolutionizing shell production. These technologies allow for precision in shaping and joining the components with minimal material waste. The efficiency of these processes is essential for providing cost-effective solutions while meeting the growing demands for energy storage systems in various markets.

On the environmental front, the trend toward eco-friendly manufacturing is essential for fostering a sustainable future. By prioritizing materials with lower environmental footprints and developing closed-loop systems for recycling, companies can significantly lessen the ecological impact of battery production. This practice encourages the recovery of valuable raw materials, reducing reliance on mining and extraction operations that often harm ecosystems.

In alignment with global sustainability goals, manufacturers are also exploring the incorporation of biodegradable elements within the battery system. Although this remains a developing area, it reveals the potential for creating not only efficient but also environmentally responsible energy storage solutions.

4. DESIGN INGREDIENTS FOR PERFORMANCE ENHANCEMENT

Design principles related to the construction of the sheet metal shell play a significant role in optimizing the performance of energy storage batteries. For instance, the thickness of the shell is a trade-off between protection and weight. A thicker shell provides enhanced protection against mechanical shock and increases thermal stability. However, an excessively heavy shell can lead to inefficiencies, particularly in applications where weight is a critical factor, such as electric vehicles.

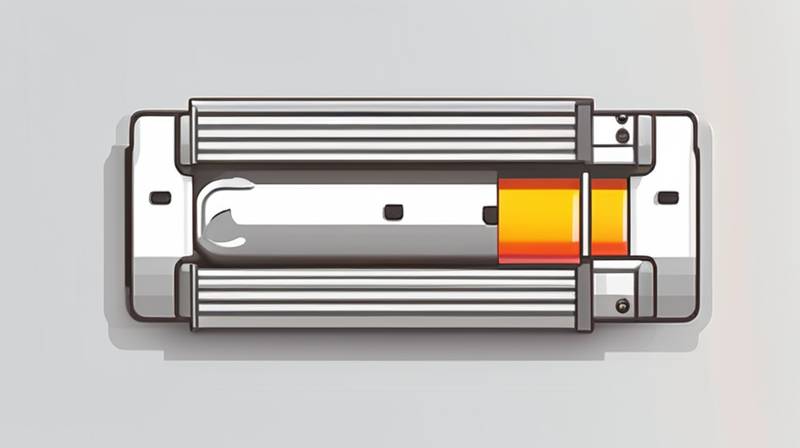

Another crucial aspect is the shape of the shell. Geometric design can influence the battery’s heat management capabilities and structural rigidity. Research indicates that shells with optimized geometries not only improve load distribution but also enhance airflow around the battery cells, promoting efficient cooling. Various shapes, such as cylindrical or prismatic designs, are explored based on specific applications and energy storage requirements.

Furthermore, intricate methods such as embossed or ribbed patterns can be integrated into the shell design. Such features can significantly improve the robustness of the shell while maintaining a lightweight structure. These patterns enhance the surface area, aiding in better heat dissipation and thus optimizing the cooling mechanisms essential for comprehensive thermal management.

Innovative technologies like modular shell designs are also gaining traction. This approach allows for flexibility and scalability in production. Modular designs can be customized to specific applications or revised as technology advances. By integrating future upgrade potentials, manufacturers can extend the lifespan and functionality of battery systems, making them more appealing in the competitive energy storage market.

5. CONNECTIONS TO ENERGY STORAGE SYSTEMS

The interconnectivity of the sheet metal shell with the broader energy storage system must be acknowledged as well. The electrical connectors housed within the shell are vital for battery operation. These connections must be designed to handle high currents while minimizing resistance and heat generation. Insulating materials within the shell’s design capacity are crucial, as inadequate insulation can lead to short circuits and performance issues.

Moreover, the integration of smart technology within the shell has become increasingly common. Smart sensors can be incorporated to monitor temperature, voltage, and state-of-charge conditions, allowing for more refined management strategies. Such advancements enable proactive measures to avoid overheating or overcharging, ensuring optimal functioning and safety of the entire energy storage system.

Additionally, communication systems within the battery shell can relay information to external devices. This data transfer capability opens avenues for advanced battery management systems (BMS) that can enhance energy efficiency and operational management. As energy demands rise and power sources diversify, the interconnections between battery technologies and smart solutions will become increasingly integral.

Furthermore, the shell must provide ease of assembly and maintenance. Designs facilitating quick access for inspection or servicing promote operational longevity while minimizing downtime. The balance of accessibility and structural integrity emphasizes the importance of strategic design thinking when it comes to energy storage solutions.

6. REGULATORY AND INDUSTRY STANDARDS

Compliance with regulatory frameworks and industry standards for sheet metal shells is another layer of complexity that cannot be overlooked. Various international standards dictate the materials, manufacturing processes, and performance metrics for energy storage systems. Adhering to these regulations ensures not only the safety but also the interoperability of battery systems across various platforms.

In many jurisdictions, manufacturers are required to conduct extensive testing regarding the mechanical and chemical resilience of the sheet metal shells. This testing often includes simulations for stress, thermal, and electrical conditions. These assessments are essential to ascertain the reliability of the batteries under diverse operational stresses, ultimately ensuring user safety and confidence in the product.

Moreover, the industry is moving toward the harmonization of standards globally. As energy storage technologies advance, so too must the regulations governing them. Keeping pace with international conventions helps produce batteries that are not only competitive but also safe and reliable for global markets.

In addition, industry collaboration is vital for creating better standards and practices. Working together, companies can share findings and develop comprehensive frameworks that promote innovation while ensuring safety and environmental sustainability. This collective approach is essential for addressing common challenges and identifying opportunities for enhancement in sheet metal shell technologies.

COMMON INQUIRIES

WHAT MATERIALS ARE USED FOR SHEET METAL SHELLS IN ENERGY STORAGE BATTERIES?

The materials most commonly employed in the production of sheet metal shells for energy storage batteries include aluminum and stainless steel. Aluminum is favored for its lightweight properties and excellent corrosion resistance. It allows for a significant reduction in the overall weight of the battery system, making it particularly suitable for applications in vehicles and portable devices where weight is a critical factor. Additionally, aluminum can be easily molded into various shapes, offering design flexibility.

Stainless steel, on the other hand, provides enhanced strength and durability. Its robust nature ensures that the battery shell can withstand external impacts and harsh environmental conditions. While heavier than aluminum, stainless steel is particularly useful in applications where resistance to wear and tear is necessary. Manufacturers often select a material based on a specific use case, balancing factors such as weight, cost, environmental conditions, and intended user demands to optimize overall performance.

WHAT ARE THE ADVANTAGES OF HAVING A METAL SHELL VERSUS PLASTIC IN ENERGY STORAGE BATTERIES?

The advantages of employing a metal shell over plastic in energy storage batteries are numerous and significant. Firstly, metal shells provide superior strength and durability, offering protection against physical stressors. Unlike plastic, which can become brittle over time or be punctured, metal shells resist deformation and protect internal components reliably.

Secondly, metal has superior thermal conductivity compared to plastic, allowing for better heat dissipation. Efficient thermal management is crucial for battery safety and performance, as overheating can lead to reduced lifespan and safety risks. Metals facilitate optimal cooling mechanisms, which are essential during intensive usage periods.

Moreover, metal shells often have better electromagnetic shielding properties than plastic. This shielding capacity is vital in preventing interference from external electromagnetic sources, which can affect battery performance. In high-demand environments, such as automotive or industrial applications, ensuring that the battery operates without electronic disturbances is crucial.

Therefore, while plastic may be lighter and less expensive, the longevity and safety aspects of metal shells make them a more favorable choice for many energy storage solutions.

HOW DOES THE DESIGN OF A SHEET METAL SHELL AFFECT BATTERY PERFORMANCE?

The design of a sheet metal shell significantly impacts battery performance through factors like heat dissipation and structural integrity. A well-engineered shell can enhance thermal regulation, facilitating better energy transfer and minimizing the risks of overheating. Designs that promote airflow around the batteries enable heat to dissipate effectively, maintaining optimal operational temperatures during charge and discharge cycles.

Furthermore, the geometric design influences how the battery can distribute mechanical loads. Load distribution directly affects the shell’s ability to protect internal components from physical impacts, while poor design can lead to stress points that compromise battery life. An optimized design reinforces the shell’s integrity, enhancing the overall reliability of the energy storage system.

Thus, careful consideration of design elements in conjunction with advancements in manufacturing technologies can result in improved battery performance and longevity, aligning with increasingly demanding energy applications.

The sheet metal shell of energy storage batteries plays an indispensable role in various facets of performance, safety, and sustainability. Its structural integrity ensures the battery’s overall reliability, while its thermal management capabilities help to stave off overheating — a serious concern for battery safety. Moreover, advancements in manufacturing techniques coupled with innovative design approaches contribute to a growing trend towards sustainability, ensuring that energy storage solutions meet both performance criteria and environmental responsibilities. Ultimately, the future of energy storage technologies appears to be inextricably linked to the continued evolution and optimization of these vital metal shells.

Building on the foundation of robust materials, innovative design, and ongoing compliance with industry standards, manufacturers can develop sophisticated battery systems capable of meeting the demands of a rapidly changing energy landscape. As a result, stakeholders in the energy sector can gain increased confidence in energy storage solutions, ushering in a new era of efficiency, safety, and environmental sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-about-the-sheet-metal-shell-of-energy-storage-battery/