How about the sheet metal of the household energy storage chassis

1. The sheet metal utilized in the household energy storage chassis plays a crucial role due to its unique properties, durability, and cost-effectiveness. 2. The choice of materials affects the overall performance and longevity of energy storage systems. 3. Understanding the significance of these materials is essential for manufacturers and consumers alike. 4. Innovations in sheet metal technology contribute to enhancing the efficiency of energy storage solutions.

Sheet metal is a fundamental component in the design and construction of household energy storage chassis. Its importance cannot be overstated as it influences not only the mechanical strength of the units but also their thermal management and safety attributes. The materials chosen for these chassis must withstand rigorous operational demands while maintaining a lightweight profile to enhance usability and efficiency. Common grades of steel and aluminum are often favored due to their superior properties, such as resistance to corrosion, ductility, and ease of manufacturing.

When evaluating the performance of household energy storage systems, the selection of sheet metal impacts the overall functionality and reliability of these solutions. The robustness of the chassis is critical, as it must endure various environmental factors, including temperature fluctuations and potential mechanical stress. In essence, the fabrication methods and finished qualities of the sheet metal significantly contribute to the longevity and effectiveness of energy storage units. With evolving technologies, manufacturers are increasingly exploring advanced alloys and coatings to enhance the properties of traditional materials, ensuring that the industry keeps pace with changing consumer demands for higher efficiency and sustainability.

1. MATERIALS USED IN SHEET METAL FOR STORAGE CHASSIS

The suite of materials adopted for crafting sheet metal is multifaceted, encompassing a variety of metals that each offer distinct advantages. Carbon steel, known for its strength and versatility, proves to be the most commonly utilized material. This variety provides aerodynamic advantages and the necessary durability for harsh conditions, which is essential in a residential context. However, carbon steel also poses a risk of oxidation, necessitating efficient protective coatings to prolong service life.

Conversely, aluminum and stainless steel have emerged as popular choices due to their lightweight nature and corrosion resistance. Aluminum is renowned for its high strength-to-weight ratio, making it ideal for portable energy storage solutions. Furthermore, it does not rust like steel while still offering adequate strength. Meanwhile, stainless steel, though heavier, provides formidable benefits regarding longevity, making it suitable for fixed installations where weight is less of a concern. The strategic selection of these materials can significantly affect a household’s energy storage efficiency, and thus understanding their properties and applications is crucial for consumers and professionals alike.

2. MANUFACTURING PROCESSES

The manufacturing processes employed in producing sheet metal impact the quality and performance of the final product. Techniques such as stamping, bending, and laser cutting are vital in shaping metal into precise components that fit the designed functionalities of energy storage systems. Stamping, for example, involves pressing the metal into specific shapes using high pressure, which can significantly enhance the structural integrity of the chassis.

Another crucial method is hydraulic bending, allowing for complex geometries that help optimize space within the energy storage systems. These methods not only facilitate the efficient use of materials but also reduce waste generated during production. Moreover, advancements in robotic automation have streamlined these manufacturing processes, yielding higher precision and consistency. As a result, manufacturers are now able to produce energy storage chassis more rapidly while maintaining stringent quality standards. This evolution in manufacturing simultaneously boosts production rates and leads to more innovative designs, catering to the diverse preferences of consumers.

3. THERMAL MANAGEMENT

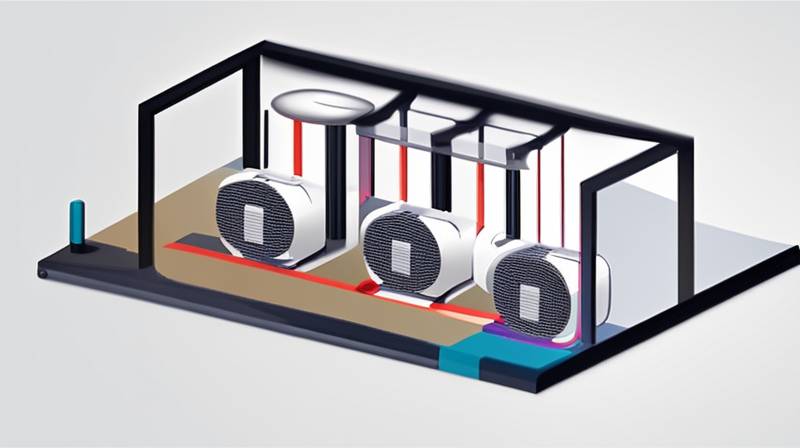

The thermal management of household energy storage chassis represents a significant challenge that is directly influenced by the sheet metal utilized in their construction. Heat generation during energy storage and retrieval demands careful management to ensure reliability and safety. If not appropriately dissipated, excessive heat can lead to decreased performance and potential failures.

Insulation materials can be used alongside the sheet metal, aiding in maintaining optimum temperatures within the chassis. Additionally, the thermal conductivity of the chosen sheet metal is critical; for instance, aluminum possesses superior thermal conductive properties compared to steel, enabling it to disperse heat efficiently. The application of thermal interface materials may also be considered to improve heat dissipation between the energy cells and the chassis. As energy storage technology advances, research continues into optimizing thermal management solutions, ensuring that performance and safety remain uncompromised.

4. FINISHING PROCESSES

After the primary shaping and fabrication of sheet metal parts, finishing processes are employed to enhance both aesthetics and functionality. Various coating applications, including powder coating and anodizing, are leveraged to improve resistance to corrosion, wear, and environmental damages. Powder coating, in particular, creates a durable finish that provides a decorative touch while maintaining resistance to scratches and chemicals.

Furthermore, surface treatments like galvanizing add a layer of zinc to steel components, significantly extending their lifespan by protecting against rust formation. The choice of finishing processes directly correlates to the intended use and environment of the energy storage system. In humid or coastal areas, for example, coatings specifically designed to combat corrosion will be vital. With numerous advancements in finishing technologies, manufacturers can not only enhance the visual appeal of energy storage chassis but also ensure optimal operational readiness and resilience in diverse conditions.

5. REGULATORY CONSIDERATIONS

Regulatory standards regarding energy storage systems necessitate careful consideration during the design and manufacturing processes. Various international and national standards dictate minimum requirements for materials used in energy storage chassis to ensure safety, efficiency, and environmental compliance. Certifications from organizations like Underwriters Laboratories (UL), for instance, are critical for ensuring products meet stringent safety requirements.

The adherence to these regulations during the selection and processing of sheet metal cannot be overstated, as violations can lead to severe legal and financial repercussions. Manufacturers must ensure that their materials and processes not only align with current regulations but also involve thorough testing and certification pathways. This rigorous adherence to standards ultimately informs the consumer about the reliability and safety of energy storage systems, gaining their trust and confidence in the products offered.

6. SUSTAINABILITY AND INNOVATION

With rising concerns regarding environmental impacts, the sustainability of materials and processes used in household energy storage is more pressing now than ever. The metal industry is witnessing a shift towards recyclable materials, with corporations gravitating towards using recycled steel or aluminum to satisfy eco-conscious consumers. This transformation not only reduces waste but conserves energy in the manufacturing process and minimizes the carbon footprint associated with raw material extraction.

Moreover, innovations in sustainable manufacturing techniques such as reducing energy consumption during production processes contribute heavily to this movement. Efforts to develop more environmentally friendly coatings and treatments further bolster the sustainability narrative. By prioritizing eco-friendliness, manufacturers not only cater to the evolving demands of consumers but also contribute to a larger global goal of reducing environmental impacts, showcasing leadership in responsibility within the industry.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SHEET METAL ARE COMMONLY USED IN ENERGY STORAGE CHASSIS?

In the realm of energy storage chassis, the most prevalent types of sheet metal include carbon steel, aluminum, and stainless steel. Each offers unique attributes critical to performance and utility. Carbon steel is prized for its strength and versatility, making it an ideal candidate for various applications, although it may require protective coatings to mitigate rusting. On the other hand, aluminum stands out for its lightweight nature and resistance to corrosion, making it suitable for those prioritizing mobility in their energy storage systems. Stainless steel, while typically heavier, offers exceptional longevity, particularly in fixed installations. Selecting the appropriate metal involves an analysis of the specific use case, including environmental factors and performance expectations.

HOW DOES MATERIAL AFFECT THE PERFORMANCE OF ENERGY STORAGE SYSTEMS?

Materials employed in household energy storage systems directly influence their overall performance, efficiency, and longevity. For instance, the thermal conductivity of the sheet metal determines how well heat is dissipated during operation, directly affecting safety and operational reliability. Metals like aluminum excel in these scenarios due to their superior thermal performance, while steel may require additional thermal management strategies. Furthermore, the weight of the metal affects portability; lighter metals can facilitate movement without sacrificing structural integrity, which is vital for users seeking flexible energy solutions. Thus, material choice is integral to ensuring that energy storage systems perform effectively and endure various conditions.

WHAT REGULATIONS MUST BE CONSIDERED IN THE DESIGN OF ENERGY STORAGE CHASSIS?

Designing energy storage chassis requires careful compliance with numerous regulatory standards that vary across regions and applications. Organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC) provide guidelines that manufacturers must adhere to, focusing on safety, durability, and efficiency. These standards cover everything from structural integrity to materials used, ensuring consumer safety and promoting product reliability. Manufacturers must remain vigilant regarding updates to these regulations to guarantee compliance. Ensuring that the products meet all necessary certifications not only protects the company but also instills confidence in end-users regarding the safety and efficiency of the energy storage systems.

The construction of household energy storage chassis fundamentally relies on the properties of sheet metal, which significantly affects their performance, reliability, and longevity. From the choice of materials and innovative manufacturing processes to considerations around thermal management, finishing applications, regulatory compliance, and sustainability initiatives, each aspect deeply intertwines to shape the functionalities of these systems. Accordingly, professionals in the field must stay informed about evolving technologies and material usage trends to ensure that they offer the best solutions in the competitive energy storage market.

Strengthening the home energy grid through resilient storage solutions is imperative as households strive for efficiency and sustainability. Those investing in these systems will find that the materials and processes incorporated into their design are equally as important as the energy they store. By prioritizing research, development, and adherence to regulatory guidelines, manufacturers can contribute positively to both the market and the environment. In sum, navigating the multifaceted aspects of sheet metal in household energy storage chassis is fundamental to optimizing performance, enhancing reliability, and promoting sustainable practices that align with modern energy demands.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-about-the-sheet-metal-of-the-household-energy-storage-chassis/