In the realm of energy storage systems, the efficiency, reliability, and safety of battery management systems (BMS) are paramount. 1. The energy storage BMS test system ensures comprehensive evaluation of performance, detects faults, and enhances safety. 2. It incorporates various testing methodologies, including functional, thermal, and safety assessments. 3. By employing advanced diagnostics, the system promotes prolonged battery life and operational efficacy. 4. Regular testing protocols mitigate risks associated with battery failures and optimize energy usage. A significant aspect of the BMS testing system is its capability to replicate real-world operating conditions to yield accurate results. This ensures that the BMS maintains not just optimal performance but also adheres to safety standards critical for both commercial and residential applications.

1. UNDERSTANDING ENERGY STORAGE SYSTEMS

Energy storage systems have become integral in managing energy supply and demand, particularly with the rise of renewable energy technologies. These systems serve to store excess energy generated during peak production times, making it available for use during periods of low production. A BMS operates to ensure that batteries within these systems function efficiently, monitoring tasks such as charging and discharging cycles.

Within the framework of energy storage, battery management systems perform an array of functions that are essential for the safety and reliability of battery operation. They include voltage regulation, thermal management, and monitoring battery health, all of which are crucial to prolonging the lifespan of energy storage systems. Essentially, a well-designed BMS test system provides insights into how batteries can be optimized for various applications, ensuring that energy storage solutions can meet the evolving demands of modern energy consumption.

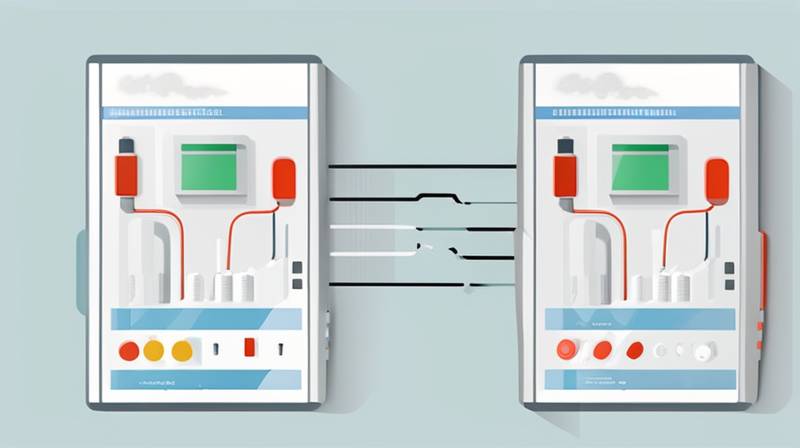

2. COMPONENTS OF A BMS TEST SYSTEM

A BMS test system comprises several integral components working in unison to ensure optimal performance. These components include sensors, microcontrollers, communication interfaces, and a robust data logging system. Each element plays a critical role in accurately assessing and enhancing the effectiveness of battery management systems.

Sensors are fundamental in monitoring the state of each battery cell. They track essential parameters such as voltage, temperature, and current, which are vital for maintaining safe operational standards. Microcontrollers interpret the data collected by sensors and execute control strategies that regulate battery operation. Communication interfaces enable the exchange of information between the BMS and external systems, facilitating real-time monitoring and decision-making based on current conditions.

3. METHODOLOGIES FOR BMS TESTING

Various methodologies are employed in testing BMS to ascertain its reliability and performance integrity. Key strategies include static and dynamic testing, thermal cycling, and fault injection. Each of these methodologies provides comprehensive insights into the operational capabilities of the management system under different conditions.

Static testing typically involves thorough inspections of the hardware and software components without initiating the system’s operational cycles. This form of testing allows engineers to evaluate the system’s basic functionalities. Dynamic testing, on the other hand, simulates real-time operation conditions, enabling the assessment of the BMS response to dynamic changes such as rapid charging or discharging scenarios.

4. FUNCTIONAL TESTING IN BMS SYSTEMS

Functional testing is a paramount methodology designed to validate the specific functionalities of the BMS. It encompasses evaluating the various operational algorithms that govern battery performance and responses to charging and discharging cycles. Through a series of scripted scenarios that mimic real-world use, functional testing helps identify potential technical flaws or limitations in the BMS.

Identification of discrepancies during functional testing is crucial for improving the design and ensuring that the BMS operates within its safety parameters. By simulating potential failures or extreme conditions, engineers can assess the BMS’s reliability and robustness, tailoring the system to handle diverse operational demands while maintaining peak performance. Ultimately, a functional testing regime not only determines compliance with design specifications but also fosters enhancements in BMS architecture.

5. SAFETY ASSESSMENTS IN BMS TESTING

Given the increasing emphasis on safety in battery management, safety assessments constitute a critical facet of the BMS testing system. Safety tests analyze how the BMS stands up to various hazardous conditions, such as short circuits or thermal runaway, and whether it can prevent dangerous scenarios from occurring.

Implementing thorough safety assessments ensures that all vulnerability points are examined, effectively mitigating potential risks associated with battery failures. These evaluations often involve stress-testing the BMS to its limits, thereby ensuring that every aspect functions as intended under extreme conditions. By identifying and addressing weaknesses during this testing phase, manufacturers can enhance the reliability and safety of their products in real-world applications.

6. OPTIMIZATION THROUGH TESTING

Continuous improvement and optimization of battery management systems are essential for adapting to the fast-paced advancements in energy storage technologies. Rigorous testing and analysis reveal data-driven insights that inform necessary modifications to refine system algorithms and improve energy efficiency.

Refinement processes not only focus on enhancing the accuracy of the BMS’s monitoring capabilities but also empower it to optimize charging and discharging cycles intelligently. Moreover, advancements in machine learning and AI are being increasingly integrated into BMS testing processes, facilitating predictive analytics that enhance operational strategies and longevity of battery systems.

7. REGULATORY COMPLIANCE IN BMS TESTING

Regulatory compliance is an essential consideration that shapes the standards and protocols followed in BMS testing. Energy storage systems must adhere to specific guidelines established by governing bodies to ensure safety and reliability. These regulations are put in place to protect consumers and align innovations with public safety interests.

Achieving compliance often necessitates detailed documentation and adherence to rigorous testing procedures. Manufacturers are compelled to conduct thorough testing and validation processes, meeting or exceeding standards set forth by local and international regulatory agencies. This compliance not only safeguards public safety but also enhances the credibility of manufacturers and their products in the competitive energy market.

8. TRENDS AND INNOVATIONS IN BMS TESTING

As the energy storage industry evolves, innovative trends continue to emerge, shaping the future of BMS testing systems. The advent of digital twins, advanced sensor technologies, and Big Data analytics heralds a transformative era in how BMS are designed and validated.

Leveraging digital twins allows for the creation of virtual models reflecting real-world systems. This technology enables comprehensive simulations that anticipate performance under various scenarios without physical testing, maximizing efficiency and reducing costs. Furthermore, the integration of enhanced sensor technologies facilitates higher precision in data collection, leading to actionable insights that drive further improvements in energy management.

FREQUENTLY ASKED QUESTIONS

WHAT IS A BMS?

A Battery Management System (BMS) is a critical component in energy storage systems responsible for monitoring and managing battery packs. Its essential functions include maintaining the battery’s health, preventing overcharging and overheating, and ensuring that the energy storage system operates safely and efficiently. The BMS also communicates data about battery performance to external systems, allowing for real-time monitoring and management. Advanced BMS technologies can predict battery lifespan and performance under various conditions, enhancing the reliability of energy storage applications.

HOW DO BMS TEST SYSTEMS INCREASE BATTERY SAFETY?

BMS test systems enhance battery safety through rigorous testing protocols designed to replicate real-world conditions. By performing safety assessments, these systems evaluate the BMS’s ability to manage hazardous situations such as short circuits or thermal runaways. The testing processes identify weaknesses and vulnerabilities present within the system, enabling engineers to design solutions that mitigate risks. Consequently, a well-tested BMS not only protects the energy storage unit but also assures users of their safety, minimizing potential hazards that could result from battery failures.

WHAT FACTORS INFLUENCE BMS PERFORMANCE?

Several factors significantly influence BMS performance, including thermal conditions, battery design, and the quality of materials used. Thermal regulation is critical, as temperature fluctuations can lead to performance degradation and safety risks. The design characteristics of the battery itself, such as capacity and configuration, also affect how well the BMS manages its operational functions. Finally, the choice of materials plays a role in energy efficiency, degradation rates, and overall durability. Each of these factors must be carefully considered during the design and testing of a BMS to ensure optimal functionality.

The significance of efficient BMS testing cannot be overstated, as it not only informs improvements in technology but also safeguards users against potential hazards. Effective implementation of testing protocols leads to better-performing energy storage systems, increasing the reliability and efficiency of the overall energy infrastructure. Moreover, the rigorous assessment ensures compliance with safety regulations, fostering consumer trust and market acceptance of innovative energy solutions. The integration of new technologies in BMS testing signifies an evolving landscape, promoting smarter energy management practices and contributing to widespread sustainability initiatives. As energy storage demands grow, the evolution of BMS test systems will continue to be pivotal in addressing the challenges posed by modern energy landscapes. Thus, investment in BMS testing will yield long-term benefits for stakeholders, facilitating a reliable, efficient, and safe energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-about-the-energy-storage-bms-test-system/