High-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro has developed a prototype solar energy flywheel storage system that aims to significantly reduce costs by utilizing glass fiber composites and prestressed concrete. Founded in 2001 by Anne and André Gennesseaux, Energiestro’s mission is to create affordable energy storage solutions for the renewable energy sector.

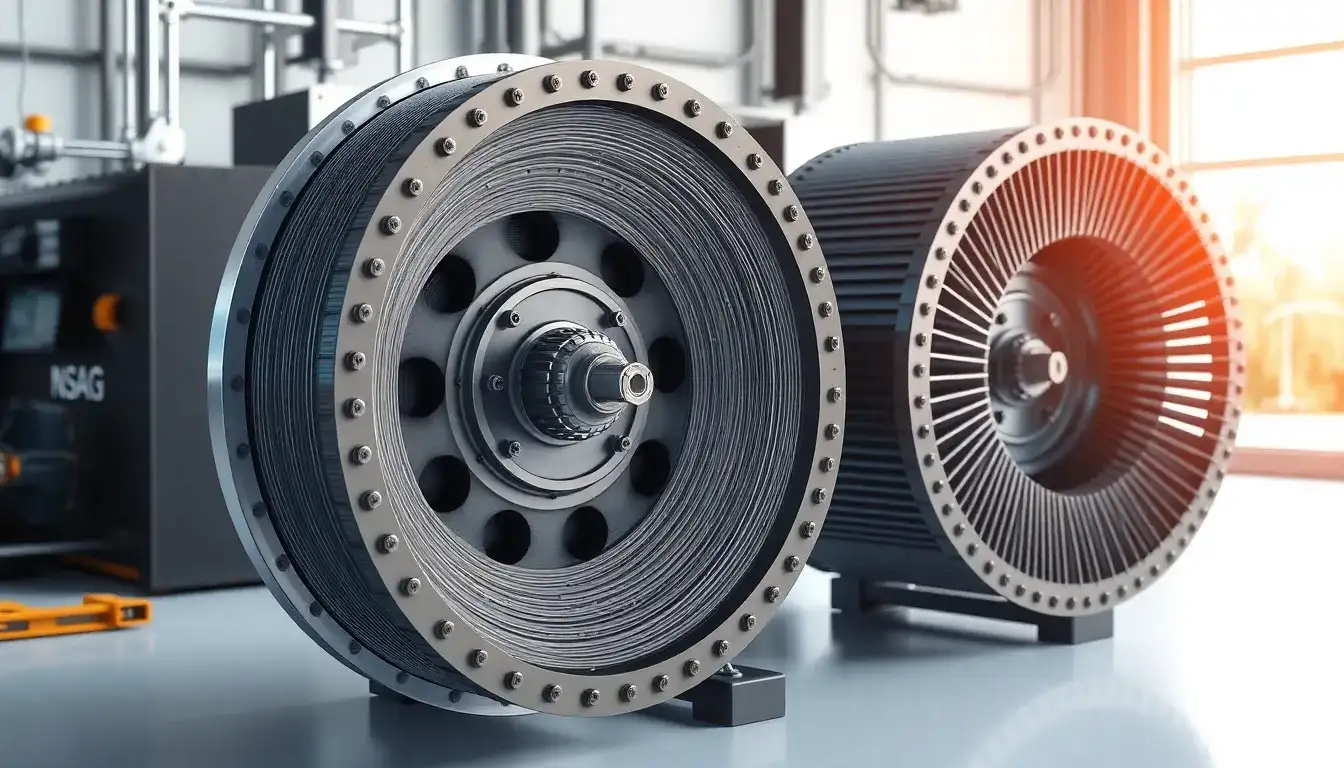

Recognizing the limitations of modern batteries—high costs, recycling challenges, and reliance on rare metals—the team pivoted to flywheel energy storage systems. These systems work by storing and releasing energy through the rapid rotation of a cylindrical rotor. Typically, the motor, alternator, and flywheel are housed in a vacuum chamber to minimize friction during rotation.

Initially, flywheel energy storage systems were constructed entirely from metal, but newer versions made with carbon fiber composites have emerged, leveraging carbon fiber’s lightweight and high tensile strength to increase efficiency. However, the cost of carbon fiber composites led Energiestro to explore more economical alternatives.

To achieve an affordable solution for underground energy storage compatible with home solar panels, the team found that concrete was the most cost-effective material. However, concrete alone lacks the strength to withstand the stresses of rotation, which can lead to inefficiencies and cracks. To address this, Energiestro decided to prestress the concrete—similar to techniques used in construction—to enhance its strength and durability.

The solution involved wrapping the concrete flywheel with a layer of glass fiber to provide the necessary compression without adding significant weight. Gennesseaux notes that this innovative combination of materials had never been utilized in this context before, which posed various design challenges throughout development.

To manufacture the flywheel, Energiestro opted for filament winding—a technique that allows for the application of glass fiber over the rotor. However, the standard commercial winding systems could not meet the high tension requirements needed to effectively compress the concrete. To tackle this issue, Energiestro partnered with Autonational Composites to design a customized vertical winding system.

Key challenges included adapting the winding system from a horizontal to a vertical orientation, suitable for the 3-ton concrete flywheel, and ensuring even resin distribution without dripping. The newly developed system is mounted on a crane to facilitate the handling of the heavy flywheel.

The team also aimed to minimize the use of glass fiber while maximizing winding tension, which is critical for cost efficiency. However, increasing tension risks breaking the glass fiber, necessitating a rethinking of the winding process. The solution involved a patented design featuring a series of rollers that gradually increase the tension on the fiber as it wraps around the flywheel.

This innovative approach allows for approximately 50 layers of glass fiber composite to be laid down at a thickness of about 2 centimeters. The finished flywheel is encased in a concrete canister and installed mostly underground, next to the solar panel system.

Currently, Energiestro’s prestressed concrete/glass fiber composite flywheel can store up to 10 kilowatt-hours of energy—sufficient to power a home overnight after charging during the day. The company has plans to scale up to larger systems capable of storing up to 50 kilowatt-hours.

The VOSS (Volant de Stockage Solaire or Solar Storage Flywheel) system is designed to be primarily buried underground, with an access hatch above ground for maintenance. It is built to last for over 30 years. Gennesseaux claims that the cost of energy storage using the VOSS system is around €20 per kilowatt-hour, which is approximately 10% of the cost of equivalent carbon fiber flywheels or lithium battery systems.

As of early 2025, Energiestro has installed two beta test systems with commercial solar panel setups and plans to install ten more during the year. These systems are produced at the company’s pilot plant in France, with ongoing efforts to secure funding for a larger factory to scale production. The ultimate goal is to provide VOSS systems for large-scale solar plants, potentially requiring around 10,000 units per facility.

“This development has taken a decade,” says Gennesseaux. “No one had created a flywheel with concrete and glass fiber like this before, which led to the development of the necessary winding technology. Now that we are operational and seeing success, we are eager to build a factory and begin large-scale production.”

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/affordable-flywheel-energy-storage-system-utilizes-high-tension-vertical-filament-winding-technique/