To determine the appropriate pipe for the connection to the solar exhaust port, several crucial aspects must be taken into account. 1. The material of the pipe is essential due to temperature resistance and durability, ensuring that it can withstand high temperatures and potential exposure to the elements. 2. The diameter of the pipe must be compatible with the exhaust port to prevent backpressure and ensure efficient airflow, which is necessary for optimal system performance. 3. Insulation properties should be evaluated as these can significantly impact energy efficiency, maintaining the system’s overall effectiveness. 4. The ease of installation and maintenance is also vital, allowing for seamless integration and future service without complications.

Elaboration on point one: Selecting the right material is paramount, as pipes made of metal, such as stainless steel, offer robustness and heat resistance, ensuring that the solar exhaust port performs well over time. Additionally, plastic alternatives, such as PVC, can be suitable if they are rated for high temperatures and UV exposure. The chosen material directly influences the longevity and reliability of the entire solar installation.

1. UNDERSTANDING SOLAR EXHAUST PORTS

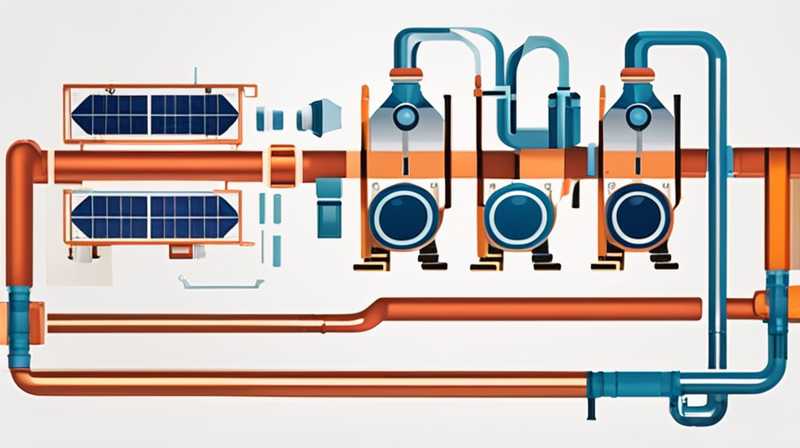

Solar exhaust ports serve a critical purpose in solar energy systems, specifically in ventilating heat generated during the operation of solar collectors or panels. To fully comprehend their significance, it is essential to grasp how these components function within the broader context of solar technology and energy efficiency.

Solar energy systems primarily harness sunlight to generate power or heat, producing energy that can be stored or used immediately. The exhaust port facilitates the release of excess heat, which can accumulate in the system during peak operating conditions. This prevents overheating, which could potentially damage sensitive components and compromise efficiency. By maintaining optimal temperatures, solar systems can operate effectively, extending their lifespan and ensuring reliable performance.

Moreover, the design of the exhaust port must align with the heating system it complements. An effective exhaust design might involve considerations around airflow dynamics, ensuring that heated air can escape without creating pressure buildup. The choice of the appropriate pipe ensures that this process is efficient, allowing for swift and unobstructed ventilation.

2. FACTORS TO CONSIDER WHEN CHOOSING PIPE MATERIAL

When selecting a pipe to connect to the solar exhaust port, understanding the various material options is crucial. Common materials include metals, plastics, and composites, each with unique properties that influence both performance and longevity.

Metals, particularly stainless steel and aluminum, are notable for their durability and thermal resilience. Stainless steel, for instance, is not only able to withstand high temperatures but also offers corrosion resistance in outdoor environments. This is particularly advantageous, as solar systems often operate in varying climates, exposed to the elements. An aluminum pipe may be lighter and easier to handle but could require additional protective coatings to enhance its resistance to oxidation, especially in coastal areas where salt exposure is significant.

In contrast, plastic options, such as PVC and CPVC, can also serve effectively if they carry the appropriate temperature ratings. PVC is lightweight, economical, and resistant to corrosion, making it a common choice for solar exhaust applications. However, one must verify that the chosen plastic can handle the temperatures generated by the solar energy system without warping or degrading over time. The integrity of the materials selected for these pipes directly affects the performance of the solar energy system, which should not be overlooked.

3. DETERMINING PIPE DIAMETER AND AIRFLOW REQUIREMENTS

The duct diameter significantly influences the efficiency of airflow in solar exhaust applications. A correctly sized pipe ensures optimal airflow, mitigates backpressure, and enhances overall performance. If the pipe diameter is too small, backpressure can impede the exhaust process, leading to heat retention which could harm the efficiency of solar systems. Conversely, an overly large pipe may lead to poor velocity of exhaust air, making it challenging for the system to evacuate air rapidly.

Designing an effective exhaust system involves calculating the required diameter based on the volume of air that needs to be expelled. This calculation can be based on the expected temperature rise in the solar system and its overall heat output. By employing formulas related to fluid dynamics, one can establish the ideal size, ensuring that the air can flow freely without bottlenecks that could disrupt the system’s operation.

Another critical aspect is to consider the layout of the exhaust piping. Straight runs are preferred as they reduce turbulence and enhance airflow. If bends are necessary, they should be gradual to minimize resistance and maintain efficiency. Thus, the design should integrate pipe diameter, layout, and materials collaboratively to create a high-functioning solar exhaust system.

4. INSULATION AND TEMPERATURE MANAGEMENT

While selecting the correct pipe material and diameter is vital, addressing insulation and temperature management for the pipes also plays an essential role in optimizing solar exhaust systems. Heat insulation protects pipes from losing valuable heat during transit. This is particularly crucial for systems where retaining heat improves overall efficiency. Adequate insulation can also protect piping from thermal expansion, which may cause premature wear or leaks.

Several insulation materials are available, offering varying levels of thermal resistance. Foam insulation is commonly used due to its excellent thermal properties and ease of installation. Proper installation of insulation is crucial to ensure that every section of the pipe is encompassed and that there are no gaps for heat escape, which would negate the advantages provided by the insulation material.

Moreover, it is essential to consider the effect of local climate conditions on temperature management. In colder climates, pipes may require additional insulation to prevent heat loss, while in warmer climates, the focus may shift towards providing ventilation to ensure that accumulated heat does not cause damage or inefficiency. This adaptability in approach is vital for an effective solar exhaust system.

5. INSTALLATION AND MAINTENANCE CONSIDERATIONS

Installing the correct pipe to the solar exhaust port is a crucial aspect that demands careful attention. Proper installation guarantees that the exhaust system operates at its peak performance and longevity. Key factors during installation include ensuring that all connections are secure and leak-free, which can significantly diminish the risk of exhaust fume accumulation, leading to efficiency loss.

One critical aspect of installation is the orientation of the piping. Uphill or downhill runs can affect drainage and airflow; therefore, it is advisable to ensure that the pipe runs are as level as feasible to encourage efficient air passage. Additionally, employing quality seals and fittings designed to withstand the thermal dynamics of the system plays a significant role in preserving the system’s efficiency.

Maintenance of the solar exhaust system should not be neglected once installed. Periodic checks for any signs of wear, corrosion, or clogs can prevent long-term performance issues. Inspecting joints and connections for leaks and ensuring the insulation remains intact can significantly contribute to the system’s operational success. Regular maintenance extends the lifespan of the entire solar energy system and sustains its efficiency over time.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF MATERIALS ARE COMMONLY USED FOR SOLAR EXHAUST PIPES?

Several materials are used in solar exhaust applications, with each offering distinct benefits. Metals such as stainless steel and aluminum are popular choices due to their durability and ability to handle high temperatures. Stainless steel is particularly advantageous for outdoor installations owing to its resistance to corrosion, while aluminum is lighter but needs protective coatings in certain environments to prevent oxidation.

On the alternative side, plastics like PVC and CPVC may also be adequate options if their temperature ratings match the environmental conditions of the solar system. PVC is lightweight and cost-effective but must be carefully selected to prevent warping under high-temperature conditions. Ultimately, the most suitable choice depends on an evaluation of both environmental factors and specific operational requirements.

HOW DOES PIPE DIAMETER IMPACT SOLAR SYSTEM PERFORMANCE?

The diameter of the pipe has a critical effect on airflow and system performance. If the diameter is too small, it can lead to backpressure, which may cause heat to overload within the system. This overheated environment can result in inefficient operation and even potential damage to the solar energy apparatuses.

Alternatively, if the diameter is excessively large, it can affect the velocity of the exhaust air, allowing poor control of heat evacuation. Proper calculations concerning airflow requirements, based on the system’s output and expected temperature rises, help ensure that the right diameter is selected. Thus, maintaining optimal air pressure and flow is imperative for maximizing solar system efficiency.

WHAT IS THE IMPORTANCE OF INSULATION IN SOLAR EXHAUST SYSTEMS?

Insulation is essential in solar exhaust systems as it impacts energy efficiency and operational effectiveness. Proper insulation ensures that heat is retained within the piping, preventing energy loss that could diminish the system’s performance. Insulation also has a protective function, safeguarding pipes from thermal expansion and potential damage due to environmental conditions.

Selecting the appropriate insulation material must consider local climate conditions and the temperature ranges experienced by the pipes. Maintaining insulation in good condition requires periodic inspections, as gaps or wear can lead to significant efficiency losses. Therefore, insulation plays a vital role in ensuring optimal operational standards in solar exhaust systems.

A purposeful selection of the proper pipe to connect to the solar exhaust port can greatly enhance the overall efficiency of solar energy systems. Consideration of various materials, pipe diameter, insulation, and installation practices ensures that airflow dynamics are optimized and heat is effectively managed. Making informed decisions at each stage of the process can lead to a robust and reliable solar energy solution. Investing time and resources to evaluate these aspects not only maximizes efficiency but also extends the operational lifespan of solar systems, ultimately contributing to sustainable energy solutions. Continual learning and adaptation in response to emerging technologies and methodologies further enhance effectiveness in this evolving field.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-pipe-should-be-connected-to-the-solar-exhaust-port-2/