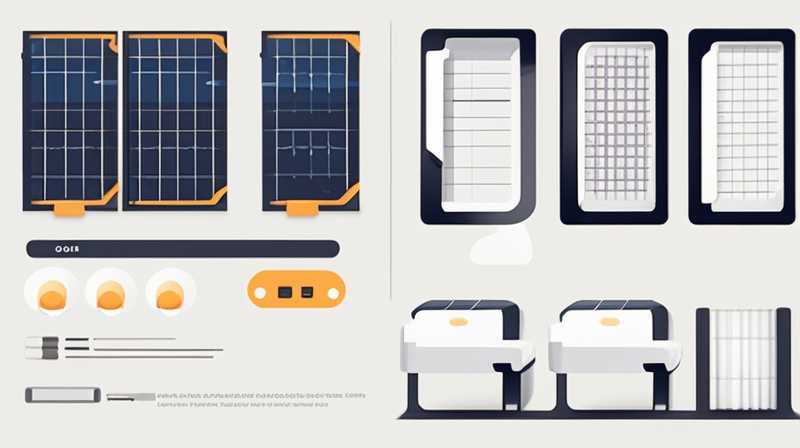

Solar panels are primarily constructed from 1. silicon, 2. glass, 3. encapsulants, 4. backsheet materials. Silicon serves as the core semiconductor, capable of converting sunlight into electricity. There are two main types: monocrystalline, which offers high efficiency and space-saving design, and polycrystalline, which provides a more cost-effective option with a slightly lower efficiency. Glass protects the delicate components from environmental factors such as weather and debris while maximizing light transmission for optimal energy production. Encapsulants, typically made from ethylene vinyl acetate (EVA), are utilized to bond the solar cells to the glass and backsheet, ensuring durability and protection against moisture intrusion. Additionally, the backsheet is crucial for electrical insulation and shielding against physical damage. For each component, specific manufacturing processes and material quality impact overall efficiency, longevity, and performance of solar panels. Notably, advancements in material science continue to enhance the durability and efficiency of these components, underscoring the importance of ongoing research in the renewable energy sector.

1. SILICON IN SOLAR PANELS

Silicon stands as the foundational element in most solar panels, functioning as the pivotal semiconductor material. Photovoltaic cells convert sunlight directly into electricity, and silicon’s properties make it particularly well suited for this purpose. Two principal types of silicon are employed in solar technology: monocrystalline silicon and polycrystalline silicon.

Monocrystalline silicon is derived from a single crystal structure, making it the most efficient type for solar panels. With the highest power output per square meter, panels composed of monocrystalline silicon are particularly valuable in settings with space constraints. Over the years, advances in manufacturing processes have increased the purity and efficiency of monocrystalline solar cells, ushering in notable performance improvements. Conversely, polycrystalline silicon consists of multiple crystal structures, which tend to offer a more affordable alternative but usually come with a reduction in overall efficiency. Both types have their advantages, allowing consumers to make choices based on budgetary and spatial considerations.

2. GLASS AS A PROTECTIVE LAYER

The role of glass in solar panel construction goes beyond mere aesthetics; it serves as a protective barrier against various environmental factors. Typically, tempered glass is used, which is specifically designed to endure physical stresses, resist impact, and withstand the elements. The transparency of the glass allows sunlight to penetrate and reach the underlying silicon cells, ensuring maximal energy generation.

One critical feature of solar glass is its anti-reflective coating, which minimizes reflections and optimizes light absorption. This aspect is essential since even marginal improvements in light penetration can lead to significant boosts in energy output. The glass layer also enhances the longevity of solar panels by shielding delicate internal components from rain, hail, snow, and dust accumulation. Studies show that high-quality solar glass can improve performance longevity by enhancing resilience to temperature fluctuations and weather extremes.

3. THE ROLE OF ENCAPSULANTS

Encapsulants serve as the binding agent that secures the solar cells within the panels, ensuring that components remain intact under various conditions. Ethylene Vinyl Acetate (EVA) is the most commonly used encapsulant, providing not only a layer of adhesion but also a safeguard against moisture and environmental pollutants that can impair performance.

The application of encapsulants is critical during the manufacturing phase. They are injected between the glass and the solar cells and then subjected to heat to create a durable bond. This process not only protects the solar cells but also helps in maintaining structural integrity over time. The encapsulant must be transparent and exhibit minimal yellowing, as any degradation would compromise light transmission and thereby reduce the panel’s effectiveness.

Moreover, advancements in encapsulant materials are focused on enhancing their performance under UV exposure and high temperatures. Next-generation encapsulants are being developed to improve resilience, thus extending the lifespan of solar panels and guaranteeing optimal performance throughout their operational life.

4. BACKSHEET MATERIALS AND THEIR IMPORTANCE

The backsheet plays a crucial role in solar panel construction, serving as the outermost layer on the rear side of the panel. This material functions as an electrical insulator, keeping the electrical components safe while resisting chemical and environmental degradation. Backsheets are often composed of polymer materials that provide both durability and lightweight characteristics.

Different types of materials can be used for backsheets, but polyvinyl fluoride (PVF) and polyethylene terephthalate (PET) are among the most common choices, thanks to their impressive insulation properties. A high-quality backsheet ensures that moisture does not penetrate the solar panel and maintains its operational efficiency over time. Furthermore, backsheets contribute to the overall aesthetic appeal of solar modules, as they can be rendered in various colors and finishes.

Continuous advancement is being made in backsheet materials to enhance performance, durability, and environmental resistance. Innovations such as developing backsheet composites that improve reflectivity or utilizing recycled materials signal a promising future for enhanced solar technology.

5. ADVANCEMENTS IN SOLAR PANEL MATERIALS

Research and development in solar panel materials have accelerated dramatically due to the growing demand for renewable energy. Material scientists are continually exploring novel substances and combinations that promise improved efficiency, lower production costs, and increased durability. One significant trend is the investigation into perovskite solar cells, which utilize a unique crystal structure that allows for potentially higher efficiencies than conventional silicon-based cells.

Perovskite materials are notably less expensive to produce than traditional silicon cells, primarily because they can be fabricated using simpler manufacturing techniques. Their versatility allows them to be incorporated into diverse environments, including flexible solar panels that can be integrated into clothing, backpacks, and even building materials. Ongoing research focuses on overcoming challenges related to long-term stability and scalability of perovskite materials within commercial applications.

Moreover, sustainability has emerged as a crucial factor in the development of solar panel materials. Efforts are underway to minimize the environmental impact of the production processes and consider end-of-life recycling options. The goal is to create solar panels that not only generate clean energy but also utilize eco-friendly materials throughout their lifecycle.

COMMON INQUIRIES

WHAT ARE THE MAIN COMPONENTS OF A SOLAR PANEL?

Solar panels comprise various essential components that work in concert to convert sunlight into electricity. Primarily, they consist of silicon solar cells, protective glass, encapsulants, and backsheets. The silicon solar cells are responsible for generating direct current (DC) electricity upon exposure to sunlight. Glass serves as a protective barrier, ensuring that the solar cells and encapsulations remain intact while allowing maximum sunlight penetration. Encapsulants, typically made from EVA, bond the cells together, providing moisture protection and enhancing durability. Finally, the backsheet serves as an electrical insulator, protecting against moisture and environmental degradation. Each of these components plays a vital role in the efficiency, longevity, and performance of solar panels.

HOW DOES SILICON AFFECT SOLAR PANEL EFFICIENCY?

The type of silicon used in solar panels significantly influences their overall efficiency. Monocrystalline silicon panels tend to yield higher energy output compared to their polycrystalline counterparts due to their uniform crystal structure, allowing electrons to flow more freely. Consequently, monocrystalline panels are typically more efficient, often achieving efficiencies exceeding 20%. Conversely, while polycrystalline options are usually more affordable, they often possess slightly lower efficiency ratings, typically ranging from 15% to 17%. Temperature resistance and performance in shaded conditions are also impacted by the silicon type. Ultimately, selecting the appropriate silicon type is crucial for achieving the desired energy output and making an informed investment.

WHAT INNOVATIONS ARE SHAPING THE FUTURE OF SOLAR PANEL MATERIALS?

The future of solar panel materials is being shaped by various innovative developments aimed at enhancing efficiency, sustainability, and affordability. The exploration of perovskite solar cells, which promise higher efficiency rates and lower production costs, is a significant advancement in the field. Researchers are also focusing on improving the durability and stability of these materials to ensure they can last as long as traditional silicon panels. Additionally, efforts to integrate recycling methods for end-of-life solar panels and the use of bio-based materials further reflect the growing emphasis on sustainability within the industry. These innovations suggest a transformative phase ahead for solar technology, paving the way for broader adoption and more efficient renewable energy solutions.

Successful integration of advanced materials is essential for optimizing solar energy capture and contributing to sustainable power generation. The array of components, including, but not limited to, silicon, glass, encapsulants, and backsheets, are continuously evolving to enhance efficiency, performance, and longevity. Innovations such as advanced perovskite cells and improved encapsulation processes reflect a burgeoning interest in reducing costs while maximizing output. As the world grapples with climate change and a escalating demand for renewable energy, the ongoing development of solar panel materials becomes increasingly pivotal. The industry must adopt a multi-faceted approach that embraces not only the technological advancements in solar materials but also their sustainable production and end-of-life considerations. Such a comprehensive focus will harness the full potential of solar energy, paving the way for a cleaner, greener future. The commitment to research and development in this space will ensure solar panels remain a cornerstone of renewable energy solutions, ultimately contributing to global efforts in combating climate change. Therefore, the materials that constitute solar panels must continue to evolve, matching industry requirements, environmental imperatives, and consumer expectations. Only through this rigorous pursuit of innovation can solar energy realize its full promise and impact on the world.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-materials-are-solar-panels-made-of-9/