Thermal insulation cotton serves as a vital component for enhancing energy efficiency in solar tubes. 1. The application of thermal insulation cotton assists in minimizing heat loss, 2. offering significant cost savings on energy bills, 3. improving the overall system performance, 4. and extending the lifespan of the solar tubes. By effectively wrapping thermal insulation cotton around solar tubes, users can ensure optimal energy retention and enhanced functionality. This process involves careful measurements, proper material selection, and the right wrapping technique, which maximizes insulation efficiency.

1. UNDERSTANDING THERMAL INSULATION COTTON

Insulation materials have become increasingly important as the environment shifts towards energy conservation and sustainability. Thermal insulation cotton is a popular choice due to its lightweight nature and impressive insulation properties. In the context of solar tubes, it surrounds the tube’s exterior, creating a barrier that significantly reduces heat loss.

Understanding the composition of thermal insulation cotton provides insights into its effectiveness. This material consists of fiber that can resist heat flow, and its structure facilitates the encapsulation of air, an excellent insulator. Such properties make thermal insulation cotton ideal for hot water solar tube applications where retaining heat is crucial. Consequently, employing this cotton during installation or maintenance can lead to a more efficient solar heating system.

2. IMPORTANCE OF WRAPPING INSULATION AROUND SOLAR TUBES

Ensuring that solar tubes are well-insulated is imperative for the effective functioning of solar thermal systems. The benefits of wrapping insulation around solar tubes include minimizing energy loss and ensuring a consistent temperature of the fluids within the tubes. This insulation not only boosts the overall energy efficiency of the installation but also enhances the durability of the solar tubes themselves.

The reasons for insulating solar tubes extend beyond simple energy retention. For instance, insulating these tubes protects them from external environmental factors, such as freezing temperatures or harsh UV rays. In regions where winters can be brutal, failure to insulate can lead to frozen pipes and operational inefficiencies. As such, investing the time and resources to correctly wrap thermal insulation cotton can safeguard the system’s integrity and performance, providing significant long-term benefits for users.

3. MATERIALS REQUIRED FOR WRAPPING

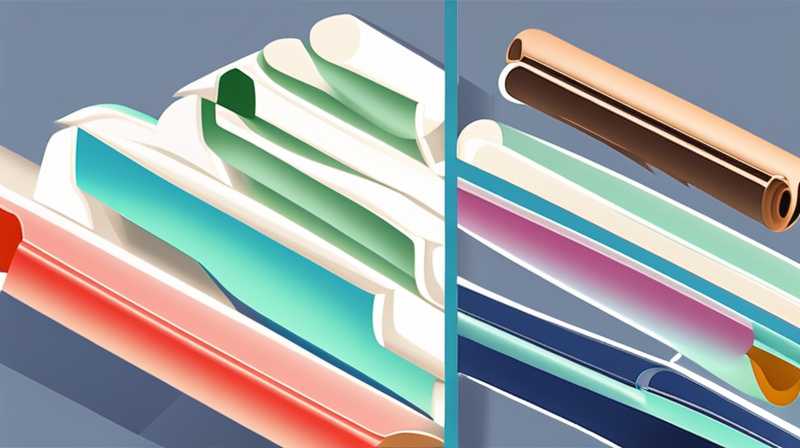

Before embarking on the insulation process, it is essential to gather the necessary materials to ensure a successful wrapping project. The primary material required is thermal insulation cotton, but several other items play a crucial role in the wrapping project. This includes measuring tape for accurate sizing, utility scissors for cutting insulation, adhesive tape for securing the insulation in place, and possibly a protective cover for additional shielding.

Each of these items serves a specific function in the overall insulation process. The measuring tape assists in determining the correct length of insulation needed. Precision in measurement fosters a snug fit that enhances thermal efficiency. Utility scissors play a pivotal role in handling the cotton safely, ensuring no damage occurs during the cutting process. Lastly, the adhesive tape complements the insulation cotton, securing it against the solar tubes and maintaining its placement throughout its lifespan.

4. MEASURING THE SOLAR TUBES

Accurate measurements are critical when wrapping insulation around solar tubes. Miscalculations can lead to inadequate coverage, resulting in inefficiencies that defeat the purpose of insulation altogether. To effectively measure, one must carefully take the diameter and length of each solar tube.

Begin by using a measuring tape to establish the circumference of the solar tube, which can be calculated by multiplying the diameter by 3.14. The length of insulation needed is simply the length of the solar tube. Recording these measurements will provide a precise framework for cutting the thermal insulation cotton. Taking the time to measure carefully will ensure that the final product is efficient and effective, preventing potential issues related to gaps or inadequate coverage.

5. CUTTING THE THERMAL INSULATION COTTON

After diligent measurement comes the crucial phase of cutting the thermal insulation cotton to size. This step should be undertaken with attention to detail in order to maintain the integrity and effectiveness of the insulation. Using utility scissors, cut the measured lengths of thermal insulation cotton according to the recorded dimensions.

When cutting, ensure that the edges are smooth to prevent any choking hazards and facilitate a proper fit around the solar tube. A well-cut piece of insulation will lay evenly, which is vital for optimal insulation performance. Ensuring uniformity and consistency in the cotton’s shape and size allows it to serve its purpose more effectively, resulting in enhanced thermal performance.

6. WRAPPING TECHNIQUE

Engaging in the wrapping process is where precision and care are paramount. Starting at one end of the solar tube, position the cut thermal insulation cotton at the base, ensuring that the cotton encompasses the entirety of the tube. Carefully wrap the insulation around the tube, observing for any gaps that could undermine the insulation’s effectiveness.

Utilizing adhesive tape, secure the insulation in place as you continue to wrap. It is advisable to overlap the insulation slightly to ensure complete coverage. This method is particularly critical for areas exposed to varied temperatures and harsh climatic conditions. Employing a tight wrapping technique can also enhance insulation efficiency, avoiding the necessity for frequent adjustments in the future.

7. SEALING AND FINALIZING THE WRAP

Once the insulation has been wrapped around the solar tubes, attention must be given to sealing the edges properly. Using adhesive tape, reinforce the ends of the insulation to ensure that it remains intact and effectively adhered to the tube. This important step will also enhance the aesthetic quality of the installation while offering an extra layer of protection against water and other environmental elements.

Careful attention to detail during sealing will prevent potential moisture intrusion, which could compromise the insulation and the solar tubes. Completing the sealing process establishes a long-lasting and efficient insulating layer, ultimately contributing to the optimal performance of the solar heating system.

8. MAINTENANCE OF INSULATED SOLAR TUBES

To maximize the longevity and effectiveness of insulated solar tubes, regular maintenance is essential. Scheduled inspections help identify any signs of wear or damage, allowing for timely repairs that will sustain the insulation quality and performance of the system. Areas of the wrapped insulation should be cleaned gently, removing any accumulated dirt or debris that could hinder performance.

In case of any visible damage to the insulation, prompt action should be taken to either repair or replace the affected area. Keeping a close eye on the insulation’s state will aid in preserving the efficiency of the solar heating system, prolonging its operational lifespan and sustaining optimal thermal performance.

9. COMMON MISTAKES TO AVOID

During the insulation process, several missteps can detract from the effectiveness of the thermal insulation cotton. One of the most prevalent errors is inadequate measurement, leading to insufficient coverage that may result in energy loss. Additionally, failing to secure the insulation properly can create gaps that allow for heat exchange, diminishing the benefits of the insulation.

Another common oversight is neglecting to inspect the insulation over time. Regular checks enhance awareness of any wear, ensuring timely interventions before minor issues escalate into significant losses. Avoiding these pitfalls enhances the efficiency and durability of the entire solar heating setup.

10. EVOLVING TECHNOLOGIES IN SOLAR TUBE INSULATION

With advancements in technology, new materials and methods for insulating solar tubes continue to emerge. Innovative insulation solutions aim to provide enhanced efficiency, durability, and adaptability. These cutting-edge materials can often surpass traditional thermal insulation cotton in terms of insulating capabilities, thermal performance, and environmental impact.

Additionally, smart insulation technologies that can self-regulate temperature or monitor thermal performance are becoming increasingly accessible. These advancements promise to improve the energy efficiency of solar heating systems significantly, paving the way for a more sustainable future in energy consumption. As users explore insulation options, staying informed about evolving technologies will help them make well-informed decisions that optimize their systems’ performance.

COMMON INQUIRIES

WHAT ARE THE ADVANTAGES OF USING THERMAL INSULATION COTTON?

The utilization of thermal insulation cotton manifests several advantages that contribute to energy conservation and system efficiency. Primarily, this type of insulation drastically reduces heat loss, ensuring that solar water heating systems retain optimal temperatures. This increase in energy efficiency translates to cost savings, as energy consumption decreases, leading to lower utility bills.

Furthermore, thermal insulation cotton enhances the longevity of solar tubes by shielding them from various environmental factors. Protecting the tubes from harsh weather, such as frost and UV radiation, minimizes wear and tear, thus extending their operational lifespan. In essence, harnessing thermal insulation cotton enhances the effectiveness and sustainability of solar heating systems while promoting environmentally-friendly energy solutions.

HOW DOES BLANKET INSULATION COMPARE TO FOAM INSULATION IN SOLAR TUBE APPLICATIONS?

When selecting an insulation type for solar tubes, users often ponder the merits of blanket insulation versus foam insulation. Both materials possess distinct characteristics that tailor them to specific applications; however, blanket insulation tends to be more versatile due to its adaptability and ease of installation. It can often wrap around curvier surfaces more effectively.

Conversely, foam insulation, while excellent for filling gaps and providing a solid barrier, may lack the same flexibility in certain scenarios. In applications where high temperatures are a consistent factor, foam insulation may have limitations, as it can degrade over time under extreme conditions. Users must weigh these variables when determining the optimal insulation type, considering specific project requirements, budget constraints, and desired thermal performance outcomes.

HOW OFTEN SHOULD I INSPECT MY INSULATED SOLAR TUBES?

Inspecting insulated solar tubes regularly is essential for maintaining optimal performance and energy efficiency. It is advisable to conduct inspections at least once or twice a year, coinciding with seasonal changes. During these inspections, users should look for signs of wear and tear, such as peeling insulation, water damage, or any visible gaps that might have developed due to temperature fluctuations.

Regular maintenance is crucial, as early detection of issues can prevent minor problems from escalating into significant failures that could compromise the entire solar heating system. In essence, establishing a routine for checking insulated solar tubes reinforces long-term reliability while optimizing energy-saving outcomes.

The application of thermal insulation cotton around solar tubes is a vital undertaking in maintaining energy efficiency and system effectiveness. This process encompasses meticulous measurement, careful material selection, and precision in wrapping techniques. By observing best practices and taking consideration of common pitfalls, users can enhance their solar heating systems significantly.

Engaging in regular maintenance and being informed about evolutionary advancements in insulation technology further promotes the longevity and performance of the system. Each of these aspects bears great importance in maximizing the benefits of thermal insulation, ultimately leading to sustainable energy usage and cost savings. As the world continues to embrace energy-efficient solutions, taking the time to properly implement and maintain insulated solar tubes will yield transformative results in both personal utility and broader environmental impacts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-wrap-thermal-insulation-cotton-around-solar-tubes/