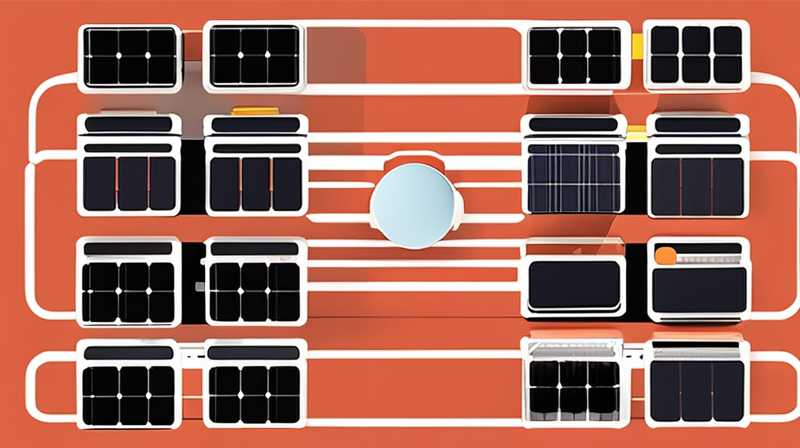

To address the issue of connecting a broken solar panel output line, one must consider several crucial aspects, including 1. Identifying the damage, 2. Selecting suitable materials, 3. Properly reconnecting the wiring, 4. Testing the system for functionality. When confronting a damaged solar panel output line, it is essential to carefully assess the extent of the damage, ensuring that the affected area is accurately identified. Additionally, utilizing high-quality connectors and tools will enhance the reliability of the repair. After gathering the necessary materials and tools, the reconnection process must be executed flawlessly, ensuring that all connections are secure and insulated. Lastly, performing comprehensive tests will confirm that the solar panel operates efficiently, restoring its functionality.

1. IDENTIFYING DAMAGE

Before proceeding with any repairs on a solar panel output line, a thorough inspection of the wiring is necessary. Pinpointing the specific location and cause of the breakage plays a vital role in ensuring that the repair is effective and durable. Various factors can lead to a broken output line, such as environmental stressors, animal interference, or wear and tear over time. Each of these factors can have unique implications for the repair process.

In conducting an evaluation, most individuals should look for visual defects like frays, cuts, or severe discolorations along the wire’s length. It is advisable to power down the solar panel system before examining the wiring. Taking the necessary precautions protects both the technician and the system from potential electrical hazards. If visual inspections reveal no apparent flaws, one might need to utilize a multimeter to check for continuity, ensuring that the electric current is flowing through the line. This thorough evaluation will provide valuable insights, guiding subsequent repair efforts with precision.

2. SELECTING SUITABLE MATERIALS

Following the identification of the problem, choosing the appropriate materials for the repair is essential. The output wire used in solar panels is typically made of copper, which possesses excellent conductive properties while remaining flexible enough to accommodate various installations. When selecting replacement wire, make sure to choose one that matches the original gauge and insulation type to maintain compatibility and performance.

Additionally, high-quality connectors and terminals are crucial for establishing a secure connection. Using subpar materials can lead to voltage drops, overheating, or even short-circuits, destroying the panel and jeopardizing safety. Heat-shrink tubing and electrical tape can provide further protection, ensuring that the connections remain insulated and shielded from environmental elements. Having essential tools, such as wire strippers, crimpers, and multimeters, on hand will facilitate a seamless repair process.

3. PROPERLY RECONNECTING THE WIRING

Once the materials have been secured, it is time to focus on the reconnection aspect. Proper techniques will ensure that the repair does not merely offer a temporary fix but instead provides a robust solution. Begin by stripping the insulation from the ends of both the existing wire and the replacement wire to expose a sufficient length of copper. A clean cut at the correct length allows for effective binding and merging of the wires.

Next, connect the two wires using appropriate connectors. If utilizing crimp connectors, ensure that the crimp connection is firm to prevent any future disconnections due to vibration or motion. Alternatively, soldering the wires may provide a more permanent and conductive connection, especially for high-load applications. When opting for soldering, applying heat shrink tubing beforehand will safeguard the newly formed connection from moisture and other external factors. After completing the connection, reinforce everything with electrical tape to ensure that the repair is both well-insulated and resilient.

4. TESTING THE SYSTEM FOR FUNCTIONALITY

After reconnecting the damaged output line and ensuring that all connections are secure, the next step involves rigorous testing to confirm the proper functionality of the solar panel system. Begin the testing process by restoring power to the solar panel and observing any indicators that suggest operational efficiency, such as LED lights or meter readings. Utilizing a multimeter again can confirm that the electric current flows correctly through the repaired line.

It is crucial to compare the output readings with standard benchmarks for similar systems to determine if the newly repaired section is functioning effectively. If discrepancies exist between the expected performance and actual readings, revisiting the repair work may be necessary. Taking the time to conduct these thorough evaluations will guarantee that the solar panel output line remains functional, sustainable, and efficient for generating clean energy.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD SOLAR PANEL OUTPUT LINES BE CHECKED?

It is recommended that solar panel output lines be inspected at least once a year. Regular maintenance helps identify potential issues before they escalate into significant problems, such as wire damage or loose connections. During inspections, one should look for signs of wear, abrasions, or environmental factors that could affect the system’s performance. Additionally, following any major weather event or excessive debris exposure, a check can help ensure that the system remains operational. Early detection allows for timely repairs and ensures maximum efficiency from the solar panel system.

WHAT TOOLS ARE REQUIRED FOR REPAIRING A BROKEN SOLAR PANEL OUTPUT LINE?

A well-equipped toolkit is vital for successfully repairing a broken solar panel output line. Essential tools include wire strippers for exposing the copper wires, crimpers for firmly connecting wires, and a soldering iron if soldering is preferred for durability. Additionally, a multimeter is essential for testing continuity and ensuring that electrical current flows correctly through the wiring. High-quality heat-shrink tubing or electrical tape should also be included in the toolkit to provide additional insulation and protection. Having all these tools readily available creates a streamlined and efficient repair process.

CAN I REPAIR MY SOLAR PANEL OUTPUT LINE MYSELF?

Yes, repairing a broken solar panel output line is feasible for individuals with some electrical knowledge and experience. However, it is imperative to prioritize safety while working with electrical components. Ensure that the solar panel system is powered down before starting any inspection or repair work. If uncertainty arises during the process or if major components need to be replaced, consulting a professional electrician or solar technician is advisable. By following the proper procedures and maintaining safety standards, one can effectively address minor damages to the output line.

**The process of repairing a broken solar panel output line can be approached with confidence when the right steps are followed. The importance of identifying damage early should not be underestimated, as it significantly impacts the overall efficiency and lifespan of the solar power system. Once an issue has been identified, careful selection of high-quality materials plays a crucial role in ensuring that repairs remain effective over time. This thorough approach includes the choice of wire gauge, insulation type, connectors, and tools, contributing to a consolidated repair process that enhances reliability. Properly reconnecting the wiring is where many missteps can occur, thus the emphasis on executing each connection methodically cannot be overstated.

Furthermore, rigorous testing after repair is indispensable in confirming the integrity and functionality of the entire solar panel system. Users can ensure these components work efficiently together, effectively turning sunlight into usable energy. For both DIY enthusiasts and those seeking professional services, understanding the fundamental steps required for this repair will lead to enhanced performance in solar energy harvesting. Above all, considering maintenance and checks as ongoing practices will help sustain energy production and extend the life of the setup. Such precautionary measures not only secure financial investments but also positively contribute to a sustainable energy future.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-panel-output-line-if-it-is-broken-2/