What happened to the old exploded solar tube?

1. The old exploded solar tube met its demise due to a combination of factors, including 1. structural weaknesses, 2. environmental stressors, and 3. maintenance shortcomings. The structural integrity of the tube was compromised by various phenomena such as temperature fluctuations, which could lead to material fatigue over time. In detail, the intricate design of solar tubes involves materials that must endure significant stress while optimizing energy absorption.

Environmental stressors, particularly extreme weather conditions—like hail, high winds, or excessive UV exposure—can significantly degrade solar infrastructure. Over time, these elements can wear down the outer layers and penetrate the inner chambers, resulting in leaks and eventually explosions. Maintenance shortcomings also played a critical role; regular inspections and repairs can prolong the life of solar installations. Without diligence, minor issues can swell into severe problems, culminating in catastrophic failures. As a result, the old exploded solar tube serves as a cautionary tale about the necessity of robust infrastructure design, ongoing maintenance, and environmental consideration in renewable energy solutions.

1. UNDERSTANDING SOLAR TUBE DESIGN

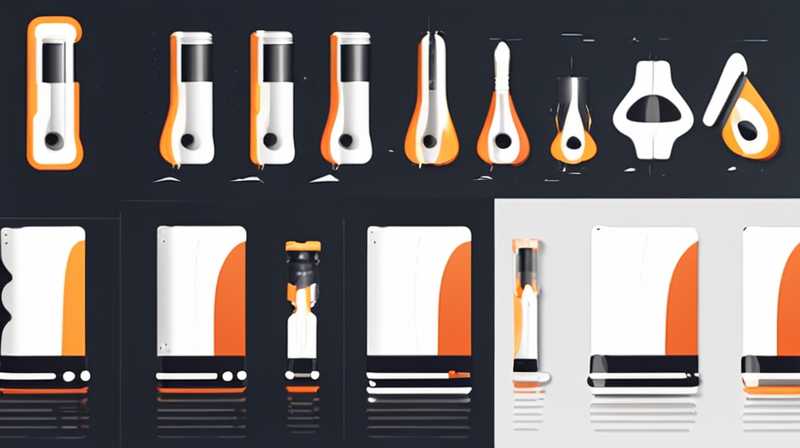

The intricate nature of solar tube design merges engineering and the principles of thermodynamics. Solar tubes, often referred to as evacuated tube collectors, rely on a vacuum-sealed system that enhances efficiency by minimizing heat loss. This technology harnesses solar radiation, converting it into usable thermal energy for heating tasks or electricity generation. While remarkably efficient, these tubes are also susceptible to design flaws, manufacturing defects, or material degradation over time.

One critical aspect of their operation involves the selection of materials that can not only withstand exposure to high temperatures but also resist corrosion and wear. When manufacturers prioritize efficiency over durability, they risk producing components that are not resilient. Insufficient testing or quality control may lead to tubes being released into the marketplace that have hidden weaknesses. These small flaws can grow more pronounced over time, resulting in catastrophic failures such as explosions. Consequently, understanding the materials and engineering principles fundamental to solar tube construction is crucial for identifying potential vulnerabilities.

2. RECOGNIZING ENVIRONMENTAL STRESSORS

The impact of environmental stressors cannot be overlooked when examining the lifespan of solar tubes. Factors such as extreme weather conditions, pollution, and even local climate characteristics collectively contribute to wear and tear on these solar collectors. For instance, hailstorms can physically damage tubes, while high winds can create vibrations that weaken their structure over time. Additionally, consistent exposure to intense UV radiation may lead to premature degradation of the materials used in construction.

Environmental influences also extend deeper; local climate factors such as humidity and temperature fluctuations significantly affect performance. Areas with frequent temperature swings can accelerate material fatigue, causing structural components to crack or warp. For instance, repeated expansion and contraction can create microfractures invisible to the naked eye, which can later manifest into larger, more significant failures. Prolonged exposure to detrimental conditions testing the limits of the materials used can escalate maintenance complications, leading to compromised safety.

3. MAINTENANCE AND INSPECTION PROTOCOLS

Effective maintenance protocols are fundamental to optimizing the operational lifespan of solar tubes. Regular inspections and strategic maintenance can significantly lower the likelihood of failures. When a system incorporates routine checks, technicians can identify early signs of degradation such as corrosion, leaks, or mechanical failures before they culminate into explosive outcomes. For solar technology, creating a comprehensive maintenance schedule is paramount for risk management.

Throughout the maintenance cycle, technicians should conduct visual inspections, assess support structures, examine seals for leaks, and evaluate thermal efficiency. Each of these checks offers insights that can inform future repairs or complete overhauls of certain components. Comprehensive documentation of inspection histories reveals trends that indicate systemic issues—it empowers technicians to act proactively instead of reactively. Emphasizing these protocols can prolong the lifespan of solar installations and ultimately minimize hazardous failures.

4. TECHNICAL LIMITATIONS AND CHALLENGES

Even the most innovative technology faces inherent limitations. The physical design of solar tubes, while efficient, introduces challenges that can hinder their operational stability. For example, the vacuum seal that enhances thermal efficiency also makes tubes particularly fragile. Should the seal become compromised, the entire system can lose efficacy, leading to overheating or even explosion scenarios.

The challenges extend to the technological aspect; as solar tube technology evolves, newer designs often outperform older installations. However, this evolution can create a disparity in efficiency, resulting in existing infrastructures being inadequately updated or replaced. The capabilities and lifespan of solar tubes are also tied to the advances in supporting technologies. As systems become increasingly sophisticated, older designs may face obsolescence without timely upgrades.

5. CAUSES OF EXPLOSIONS

Several critical factors contribute to the catastrophic explosions associated with failing solar tubes. Overheating remains one of the prime causes. When a malfunction occurs, such as inadequate heat dissipation or accumulation of pressures in sealed compartments, it can lead to a buildup of steam. If this pressure exceeds the system’s design limits, an explosion may result.

Another significant contributor involves the material integrity of the tubes themselves. Design flaws, manufacturer defects, or neglected wear can all create precarious situations. A single minute detail compromised in the manufacturing process— such as a hairline fracture—can lead to severe consequences that no routine maintenance can prevent. As a safety measure, operators should establish protocols that enable early detection of these potentially explosive conditions.

6. HISTORICAL CONTEXT OF SOLAR TUBE EXPLOSIONS

Historically, solar tube explosions have sparked debates regarding safety standards and regulations. Numerous incidents have pushed both industry leaders and regulators to reconsider what’s acceptable in terms of piping materials, installation protocols, and maintenance. These historical events underscore the critical need for establishing robust guidelines that protect both consumers and installers alike.

Many organizations have since begun conducting extensive research to improve safety protocols. As industry standards tighten, established benchmarks help new system designs undergo rigorous testing before being deemed market-ready. Historical incidents enforce awareness and the importance of revisiting previous models, leading to innovations driven by historical lessons learned.

7. REGULATORY FRAMEWORK AND SAFETY STANDARDS

The regulatory framework surrounding solar energy systems plays a pivotal role in influencing the operational standards of solar tubes. Various entities, ranging from governmental organizations to independent safety boards, stipulate requirements necessary for manufacturing and installation. Enhanced standards address safety, performance, and efficiency, aiming to minimize risks associated with exploiting solar energy effectively.

Industry leaders collaborate with regulators to develop guidelines that optimize safety and performance metrics while incorporating technological advancements. Achieving a harmonization between safety regulations and innovations ensures that systems adhere to the highest standards. By establishing comprehensive evaluations and testing protocols, industry participants can contribute to a safer solar energy landscape, ultimately preventing incidents like tube explosions in the future.

8. FUTURE OF SOLAR TUBES

Looking forward, the future of solar tubes appears promising despite the challenges and risks uncovered. Innovations in materials science and engineering continuously emerge, paving avenues for more resilient designs. These advancements aim to mitigate many of the drawbacks associated with older models, ensuring that the next generation of solar tubes can withstand extreme environmental stressors while maintaining optimal performance levels.

Moreover, as the concept of renewable energy gathers momentum globally, regulatory bodies intensify scrutiny in a bid to safeguard consumers. Enhanced safety standards paired with improved designs may foster increased public confidence in solar technology. Research institutions are also dedicating resources towards developing smarter monitoring systems, which could drastically decrease the likelihood of maintenance failures and subsequent accidents.

FREQUENTLY ASKED QUESTIONS

WHAT ARE SOLAR TUBES?

Solar tubes, also known as evacuated tube collectors, are thermal devices that convert solar energy into usable heat. The tubes consist of a vacuum-sealed structure that minimizes heat loss, maximizing efficiency. Solar tubes can be used for various applications, including residential and commercial heating, hot water systems, or even heating swimming pools. Their engineering leverages principles of thermodynamics to capture sunlight effectively, while the vacuum insulates the internal space, optimizing energy retention.

The performance of solar tubes varies based on different factors such as design, material quality, and environmental conditions. Innovations continue to emerge within the field, focusing on improving durability, efficiency, and overall functionality.

HOW OFTEN SHOULD SOLAR TUBES BE INSPECTED?

Routine inspections are crucial for maintaining solar tubes and preventing failures. It is generally recommended to conduct inspections at least once or twice a year, particularly before the onset of extreme weather conditions. Regular check-ups allow technicians to identify potential issues such as leaks, corrosion, or material fatigue before they escalate into major problems.

While annual maintenance is the baseline, certain factors may necessitate more frequent checks. Local climate conditions, overall usage patterns, and previous maintenance records should be taken into account when scheduling inspections. High-stress environments or areas prone to severe weather may require increased vigilance to ensure the system functions optimally.

WHAT CAN BE DONE TO PREVENT SOLAR TUBE EXPLOSION?

Preventing solar tube explosions hinges upon comprehensive maintenance and a proactive inspection strategy. Operators should establish detailed monitoring protocols to identify potential weaknesses early on. Regular maintenance operations should focus on checking the integrity of the material, ensuring seals are secure, and assessing heat dissipation functions.

Moreover, enhancing community awareness of potential hazards associated with solar tubes contributes to risk mitigation. By ensuring that operators understand the common symptoms of failing systems and acknowledge the importance of timely repairs, the likelihood of catastrophic incidents can substantially reduce. Education programs and community initiatives can further spread awareness about safe operational practices, fostering a culture of safety and diligence regarding solar energy systems.

The demise of the old exploded solar tube underscores critical lessons regarding infrastructure, environmental challenges, and maintenance protocols within the solar energy sector. The multifaceted nature of solar tube design calls for ongoing research and innovation to enhance their durability and efficiency. As industry standards evolve, future designs must emphasize resilience, adaptability, and regular inspections. This continuous development supports the shift toward safer renewable energy practices. Addressing past failures informs the emergence of improved technologies and regulatory frameworks. The journey of solar energy systems should stress the importance of thorough design considerations, reliable materials, and vigilant maintenance cultures, guaranteeing performance and reliability in the face of an ever-changing environmental landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-happened-to-the-old-exploded-solar-tube/