To install an angle valve for solar energy, it involves several key steps: 1. Understand the system layout, 2. Gather necessary tools, 3. Prepare the installation site, 4. Position and secure the angle valve, 5. Test for leaks. Each aspect is crucial for ensuring proper functionality and safety. A comprehensive understanding of the system layout is paramount as it ensures that the angle valve connects seamlessly with existing piping systems. Correct placement coupled with thorough preparation minimizes the risk of errors during installation. Additionally, testing for leaks after installation is vital to confirm that the valve operates efficiently without any issues.

- UNDERSTANDING SOLAR ENERGY SYSTEMS

In order to install an angle valve effectively, one must grasp the fundamental components of solar energy systems. Primarily, these systems consist of solar collectors, a storage tank, and the necessary piping. The angle valve plays a crucial role in directing the flow of fluid, typically water or antifreeze, as it circulates from the collectors to the storage tank. Depending on the design, the valve may control the flow based on temperature—ensuring that only heated water moves to the storage system.

Moreover, understanding the specific type of solar installation is essential, as various designs dictate different needs for valves. For instance, a thermosyphon system relies on the natural convection of heated fluids, while a forced circulation system uses pumps, thus necessitating different configurations for angle valve placement. Therefore, comprehending the nature of the system allows for optimal placement of the valve, enabling it to function at its best.

- SELECTING THE APPROPRIATE ANGLE VALVE

Choosing the right angle valve significantly influences performance. Various factors should be considered, such as valve material, size, and type, each affecting the overall efficiency of the solar energy system. Valves can be made from materials like brass, PVC, or stainless steel, with each option presenting distinct benefits and drawbacks concerning durability and resistance to corrosion.

Size is equally important. An incorrectly sized valve may lead to either excessive pressure loss or inadequate flow control. It’s imperative to calculate the flow requirements based on the size of the piping and the expected volume of hot water circulation. A valve that matches the specifications of the system ensures that the fluid dynamics operate at optimal levels, ultimately enhancing the efficiency of solar energy absorption and distribution.

- GATHERING NECESSARY TOOLS

Preparing for the installation requires a set of specialized tools to facilitate the process. Essential equipment includes pipe wrenches, Teflon tape, a hacksaw, and a tube cutter. Each tool plays a specific role—pipe wrenches are crucial for securing fittings, while Teflon tape aids in achieving leak-proof connections by providing a tight seal between threaded joints.

It is advisable to review the installation manual for exact requirements, as some systems may necessitate additional tools or accessories. For example, if soldering is involved, a propane torch would be necessary. By organizing all the required tools beforehand, the installation process can proceed smoothly, reducing interruptions that could affect the quality of the work.

- PREPARING THE INSTALLATION SITE

Before commencing the actual installation, preparing the site is critical for ensuring a smooth workflow. This preparation involves cleaning the area, inspecting existing piping, and ensuring that all surfaces are free of debris that might interfere with the placement of the angle valve. A clean installation area not only fosters efficiency but also minimizes risks during installation.

In addition, it is wise to check for any possible obstructions, ensuring that the angle valve can be accessed easily for maintenance purposes in the future. Positioning the valve in a location that allows for ease of service prolongs its life and ensures optimal operation throughout the system’s lifespan. Taking the time to prepare the installation site thoroughly contributes positively to the overall quality of the installation.

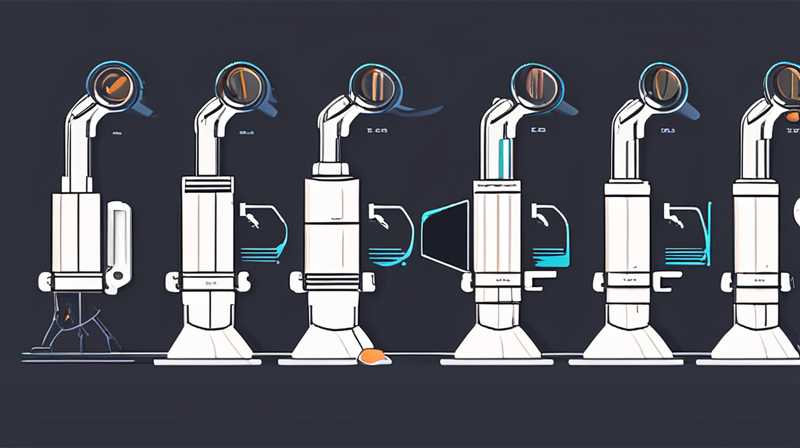

- INSTALLING THE ANGLE VALVE

Once the site is adequately prepared, the next task involves positioning and securing the angle valve. Start by measuring and cutting the piping to the appropriate lengths, ensuring clean and precise cuts to promote better-fitting joints. Using the tube cutter or hacksaw, take care to align the cuts accurately.

After cutting, deburr the edges to prevent sharp protrusions, which could compromise the integrity of the connection. Once the fittings are prepared, the valve can be placed within the piping. Teflon tape should be wrapped around the threads of the valve to ensure a tight seal. Upon securing the valve with pipe wrenches, verify that it is aligned correctly and ensure that it does not twist or turn at an angle that would affect fluid movement.

- TESTING FOR LEAKS

After successfully installing the angle valve, the immediate step involves conducting a leak test. A thorough inspection ensures that the installation was executed correctly and that all connections are secure. A simple method involves pressurizing the system and visually inspecting the valve and surrounding joints for any signs of leakage.

If leaks are detected, carefully re-tighten the fittings or, if necessary, disassemble the connections to add more Teflon tape where required. Confirming that there are no leaks is essential, as any malfunction in this area could lead to significant issues down the line, compromising overall system efficiency and possibly leading to damage.

- MAINTAINING THE ANGLE VALVE

Once everything is in place and functioning properly, maintenance practices will ensure the longevity and efficiency of the valve. Regularly inspecting the valve and the surrounding piping for signs of wear or corrosion is crucial. Over time, even the best-installed valves may develop issues that can compromise flow or lead to leaks.

Consider scheduling periodic maintenance checks every few months or following extreme weather conditions that might impact the components of your solar energy system. This proactive approach to upkeep not only enhances system performance but also fosters a deeper understanding of your installation, enabling informed interventions when necessary.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ANGLE VALVES ARE BEST FOR SOLAR ENERGY SYSTEMS?

Various types of angle valves are suitable for solar energy systems, each offering distinct benefits based on the material and mechanism used. Common materials include brass, PVC, and stainless steel, with brass being a favorite due to its durability and resistance to corrosion. The choice of valve will depend on factors such as the temperature range, the type of fluid being transported, and the overall system design. For most domestic solar installations, a brass angle valve tends to provide the best performance due to its long-lasting nature and ability to withstand higher pressures and temperatures. It’s also important to consider whether you require a manual or automatic valve, as automated solutions can offer increased efficiency through better flow control based on real-time conditions.

HOW OFTEN SHOULD I INSPECT MY ANGLE VALVE?

Regular inspections of your angle valve along with the rest of the solar system are essential for optimal performance. It is advisable to conduct visual checks at least twice a year or after major weather events that could negatively affect the system. During these inspections, look for signs of wear and tear, corrosion, or leaks around the valve and related connections. Should any issues arise, they can often be addressed before leading to significant problems. A well-maintained angle valve will help to maintain a smooth flow of fluid, ensuring that solar collectors operate efficiently and effectively. By implementing a routine inspection schedule, you can prolong the life of your solar energy system and enhance its overall effectiveness.

CAN I INSTALL AN ANGLE VALVE MYSELF?

While it is possible to install an angle valve independently, it is essential to possess a fundamental understanding of plumbing systems and solar energy technology. For those with experience in DIY projects and home maintenance, the process may seem straightforward. However, potential installation errors can lead to inefficiencies or costly repairs later on, hence engaging a professional may be a wise investment if you feel uncertain. A professional can provide expertise, ensuring that the installation meets safety standards and operates at optimal efficiency. Additionally, they may identify other system components that could require attention during the installation process, further contributing to a successful solar energy system.

It is imperative to emphasize that installation quality impacts the longevity and efficacy of the solar energy system. Proper adherence to guidelines throughout the installation process enhances operational efficiency and safety. Comprehensive understanding through diligent preparation, selecting suitable materials, and conducting thorough testing after installation will ultimately lead to higher performance and returns from solar energy systems. Investing time and resources effectively ensures a harmonious interaction between angle valves and solar technology, fostering sustainability in energy consumption. Thus, an angle valve installation is an important yet manageable task that affirms one’s dedication to transitioning toward a more energy-efficient future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-install-angle-valve-for-solar-energy/