To reconnect a broken solar light cord effectively, first, assess the damage to determine the type of repair needed. 1. Identify the breakage type, 2. Gather necessary tools, 3. Prepare the cord for reconnection, 4. Restore cold junctions, 5. Encase the repair properly. Understanding the specifics of the break will guide the best approach for fixing the cord, ensuring durability and functionality. For intricate connections, specialized connectors may be required, while simpler breaks might be repairable with soldering techniques. Proper insulation and weatherproofing ensure longevity, as solar lights are generally exposed to various environmental factors.

1. UNDERSTANDING THE BREAKAGE

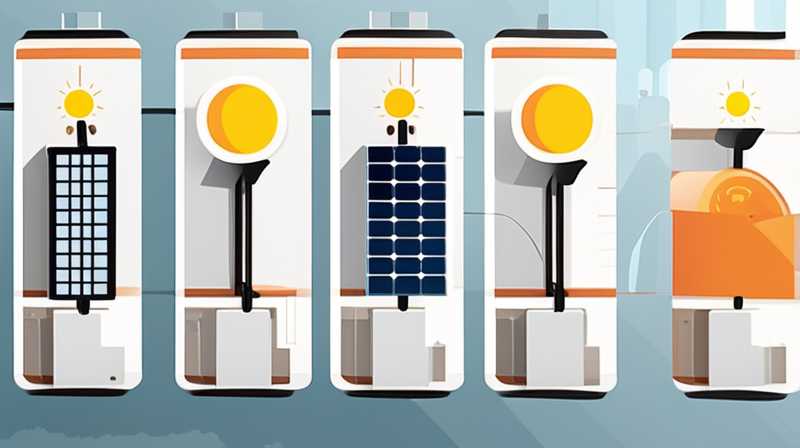

The initial step in addressing a broken solar light cord involves thorough examination. A comprehensive evaluation of the damage is essential as it helps to identify whether the break is minor, such as a simple cut or frayed wire, or more significant, such as completely severed connections. Furthermore, it is important to evaluate the components of the solar light, including the solar panel, battery, and LED fixture, to ascertain how the break impacts the entire system. Connections in solar lights are typically not standardized; understanding your specific system can guide the repair process effectively.

Once the assessment is made, the type of wire used within the solar light system should be acknowledged. In solar lights, low-voltage wiring is common, typically insulated with durable materials designed to withstand varying weather conditions. However, exposure over time can lead to wear and tear, causing breakage. Knowing whether the breakage occurs within the outer insulation or if it penetrates the inner copper wiring will influence the method of repair. This level of understanding becomes crucial in determining if simply reconnecting the cord suffices or if a more thorough replacement of components is necessary.

2. GATHERING NECESSARY TOOLS

Equipping oneself with the appropriate tools is paramount for successful repair endeavors. A well-prepared toolkit should include wire cutters, strippers, connectors, electrical tape, and possibly soldering materials. Wire cutters are used for removing damaged sections, while strippers will serve to expose the inner wiring without causing additional damage. Connectors are often pivotal to ensuring secure rejoining of the cords without soldering, making them versatile options for various break types.

It is equally beneficial to include weatherproof items in your toolkit, such as silicone sealants or heat shrink tubing. Weatherproofing materials are critical for extending the lifespan of the solar light post-repair, safeguarding it against moisture, dirt, and other outdoor elements. Once equipped, you’re ready to approach the actual repair process with confidence, knowing you can address most issues that might arise during the procedure.

3. PREPARING THE CORD FOR RECONNECTION

Preparation is key to a successful reconnection of the solar light cord. Start by turning off the solar light system to avoid any electric shock. Careful isolation of the damaged section is crucial, and this may involve cutting the wire back to a point where it is undamaged and free from any corrosion or fraying. Ensure that the area to be repaired is clean and dry, as moisture can interfere with the adhesion of connectors or soldering processes.

When faced with a severed wire, strip about half an inch of insulation from both ends of the wire, revealing the copper strands. This exposed area facilitates a robust reconnection, whether through twisting, crimping connectors, or soldering. Crimping provides a strong mechanical locking by compacting the wire strands together, while soldering offers a strong electrical bond, crucial for signal integrity and reducing resistance. Proper preparation ultimately dictates how well the repair will hold up over time.

4. RESTORING COLD JUNCTIONS

Restoring cold junctions is a fundamental aspect when rejoining solar light cords, especially when multiple wires coexist or if a connector assembly is involved. The term ‘cold junction’ refers to connections where two conductors meet and the electrical resistance is minimized for optimal conduction. Such junctions require that the approach remains consistent across the board; thus, repairing them correctly is essential.

For simple junction fixes, twist-on wire connectors can be used, which allow for a clean connection without the need for soldering. Ensure that the insulation is pulled back sufficiently to grant connectivity while not leaving exposed wiring. For instances where soldering is necessary, take care to apply even heat without overtly damaging the cord insulation. The bond created by soldering is generally more durable, providing resilience for outdoor applications. After creating this junction, inspect the area for proper insulation, sealing it to limit exposure to the elements.

5. ENCASING THE REPAIR PROPERLY

Once the connection has been reestablished, encasing the repair is critical for longevity. Utilizing electrical tape can provide an immediate protective measure, ensuring that the reconnected areas are shielded from moisture and physical abrasion. Wrap the repaired sections thoroughly, ensuring it’s tightly bound but not overly constricted. Following this step, considering the application of heat shrink tubing serves as an additional layer of protection. This tubing can be slid over the repair area, then heated to create a snug fit, thereby greatly enhancing durability against environmental exposure.

Completing this defensive measure ultimately ensures that your efforts are not undermined by future weather-related issues. The repair site should be inspected periodically, ensuring no signs of wear appear post-repair. By encasing the repair properly, you increase the lifespan and operational efficiency of the solar lighting system, making routine checks a worthwhile practice.

FAQs

WHAT TOOLS ARE NECESSARY FOR REPAIRING A SOLAR LIGHT CORD?

To effectively repair a solar light cord, essential tools include wire cutters, wire strippers, soldering tools, and connectors. Wire cutters are used to remove the damaged segment of the cord, while wire strippers help to expose the inner copper wiring without damaging it. Soldering tools allow for creating a strong electrical connection, ensuring efficient conductivity, whereas connectors offer a quick and convenient way to rejoin the wires. Additionally, having weatherproofing materials such as electrical tape or heat shrink tubing is prudent to encase the repair once completed. Ensuring your toolkit includes these items will lay the groundwork for a successful repair.

HOW CAN I TELL IF MY SOLAR LIGHT CORD IS BEYOND REPAIR?

Determining if a solar light cord is beyond repair involves assessing the extent of the damage. If the breakage or fraying extends significantly along the wire or if multiple breaks are present, repair may not be feasible. Moreover, if the internal wiring appears corroded or damaged, repairing may lead to further complications. In cases where components connect to the solar panel, such as switches or batteries, inspecting these for faults is important. If the components surrounding the cord show signs of damage or malfunction, replacing the entire unit might be the most economical solution for restoring functionality to the solar light system.

CAN I USE ANY TYPE OF CONNECTOR FOR THE REPAIR?

While many connectors are available, not all are suitable for solar light repairs. For effective reconnection, one must use connectors rated for low-voltage applications as they align with the wiring specifications of most solar light systems. Connectors designed specifically for outdoor use often provide additional weatherproofing and resistance to corrosion. As a rule of thumb, one should also ensure that the connector adds minimal resistance to the circuit to maintain optimal performance. Using the correct connectors ensures that the repair is reliable and the solar light continues to function as intended.

The necessity for mindful and informed repairs of solar light cords can’t be overstated. Understanding the intricacies of wire connections and the environmental impacts on solar lighting systems is crucial for maintaining outdoor illumination effectively. Taking the time to assess the breakage, equip with the right tools, and properly remediate damaged cords not only restores functionality but enhances longevity for these systems. By employing vigilant maintenance practices post-repair, the user can ensure that their solar lighting schemes remain operational for years to come, adapting to new technological advancements as the industry progresses.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-light-cord-if-it-is-broken/