1. One way to block the pipe opening of a solar thermal insulation barrel is by using specialized sealing materials, 2. Proper insulation from environmental elements also plays a crucial role, 3. Regular maintenance and checks prevent potential leaks from the start, 4. Understanding the construction of the barrel helps in choosing appropriate blocking techniques.

The pipe opening of a solar thermal insulation barrel serves a vital function in harnessing solar energy, and keeping it blocked when not in use is equally crucial to maintain efficiency and performance. Many homeowners and professionals might find themselves needing to seal these openings for various reasons such as winterization, maintenance, or simply to improve thermal efficiency. This article delves into effective techniques for blocking the pipe opening, exploring materials, methods, and practical tips to enhance the durability and lifespan of the insulation barrel. Ensuring a complete and thorough approach means not only addressing the physical aspects of blocking openings but also taking into account ongoing maintenance and understanding the structural design of the barrels in question for tailored solutions.

1. UNDERSTANDING SOLAR THERMAL INSULATION BARRELS

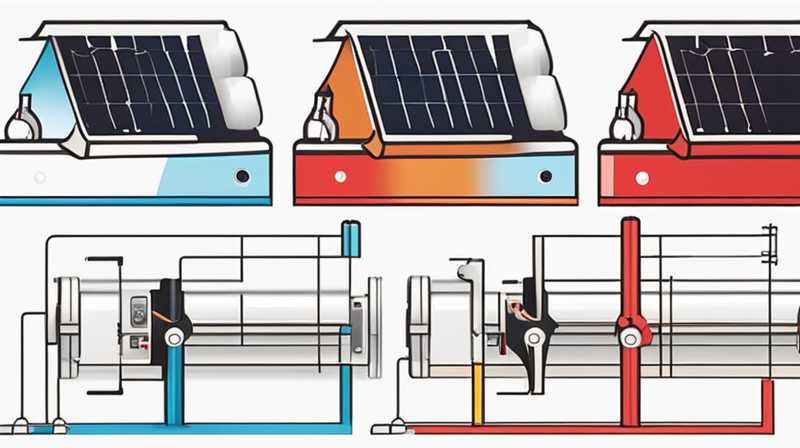

Solar thermal insulation barrels are specifically designed to enhance the effectiveness of solar water heating systems. The primary purpose of these barrels is to capture and retain heat from sunlight, providing hot water for residential and commercial applications. Proper design and insulation of these barrels ensure that the collected heat remains stable, thereby reducing energy consumption and costs.

Integration of insulation materials woven within the barrel increases energy efficiency dramatically; however, an often overlooked aspect is the plumbing that connects the barrel to the rest of the solar thermal system. These openings, if not properly managed during periods of non-use, can lead to significant heat loss or even damage due to various environmental factors. Recognizing the importance of these openings allows for preemptive measures that safeguard the overall integrity of the system.

The barrel’s structure is constructed in a way that maximizes the thermal properties of the materials used.** Knowing how these structures interact with their environment aids in selecting the most effective blocking techniques.** The next step involves methods and materials that can effectively close off these pipe openings without compromising the system’s overall functionality.

2. METHODS OF BLOCKING PIPE OPENINGS

One of the most effective techniques starts with utilizing dedicated sealing caps or plugs specifically designed for the size and type of pipe opening present. Available in various materials, such as rubber, plastic, or metal, these sealing solutions ensure a snug fit to prevent leakages when the barrel is not actively being utilized. Moreover, using durable materials extends the life of the cap, ensuring that it withstands external conditions such as rain, snow, or extreme temperatures.

Applying sealants can provide an additional layer of security. These waterproof sealants can be used in conjunction with caps to create a hermetic seal for maximum insulation. When applying sealants, it’s essential to clean the surface of any debris or moisture before use for optimal adhesion. This simple yet effective method ensures that the pipe openings remain sealed, reducing the chances of heat loss or moisture intrusion into the insulation barrel.

Yet another method involves permanent fittings such as welded caps. This can be particularly useful for those using solar thermal systems in regions with severe weather conditions, as these fittings are less likely to fail compared to removable caps. While installing welded caps might require specialized skills or tools, their ability to provide a permanent solution can outweigh the initial effort involved.

3. INSULATION MATERIALS AND TECHNIQUES

When addressing the need to block pipe openings, it is imperative to consider the insulation materials used in the construction of barrels themselves, as they dramatically affect the overall thermal performance. Insulation is typically measured by its R-value; a higher R-value indicates superior insulating properties. Common materials include fiberglass, foam board, and reflective insulation. Each material possesses unique benefits and limitations, necessitating a tailored approach when selecting insulation for solar thermal barrels.

Once the right insulation material is identified, incorporating a layer of vented insulation around the pipe opening can help to resist conduction heat loss by providing an additional thermal barrier. By preventing direct contact between the colder external air and the warm internal surface, the vented insulation facilitates a stable environment that enhances energy retention.

Regular assessment of insulation quality is essential to ensure it continues to perform effectively. Over time, insulation may degrade due to compressive forces, moisture, or prolonged exposure to high temperatures. Implementing scheduled inspections allows for the identification of potential compromise areas, ensuring that any necessary repairs or replacements occur before significant heat loss can transpire.

4. MAINTENANCE AND BEST PRACTICES

To maintain the efficiency of a solar thermal insulation barrel, regular maintenance procedures must be implemented. This not only includes checking for proper sealing around the pipe openings but also extends to inspecting the entire system for signs of wear or damage. Utilizing a checklist can enhance the effectiveness of maintenance routines, identifying actionable items during each review.

Creating a routine cleaning schedule for the solar thermal barrel is also beneficial. This involves removing debris, dust, and algae growth in the exterior, which can obstruct sunlight access and impact the barrel’s overall efficiency. When cleaning, it’s essential to use non-abrasive materials that won’t damage the insulation or the reflective surfaces of the pipes.

Furthermore, educating anyone who interacts with the solar thermal system about the importance of maintaining sealed pipe openings can mitigate any mishaps in the future. Ensuring that the knowledge is shared amongst all users promotes a culture of care and thoroughness, ultimately fostering a more sustainable energy solution for all.

5. ADDITIONAL CONSIDERATIONS FOR PIPE BLOCKING

In areas with fluctuating climates or seasonal variations, it’s paramount to consider seasonal blocking strategies. During colder months, temporary blocking may be more suitable, allowing for easy reactivation in the warmer seasons. Employing removable caps alongside insulating wraps can create a balanced approach to managing the thermal energy within the barrel while still allowing for easy access as needed.

Moreover, the positioning of solar thermal insulation barrels can also influence the effectiveness of blocking techniques. Placing the barrels in shaded areas can reduce heat gain during hotter seasons, minimizing the need for frequent blockage. Additionally, the installation of a smart monitoring system can alert users to significant temperature fluctuations, prompting immediate action to ensure the barrel’s openings are sufficiently sealed.

PIPE BLOCKING FAQS

WHAT MATERIAL IS BEST FOR SEALING PIPE OPENINGS?

Several materials effectively seal pipe openings, including silicone sealants, rubber caps, and threaded plugs. Silicone sealants offer strong adhesion and flexibility, allowing them to accommodate movements without cracking. Rubber caps can fit snugly around most pipe sizes, preventing heat loss while remaining simple to apply. Threaded fittings provide a secure closing method, ideal for long-term use. Ultimately, the choice depends on the specific circumstances and preferences regarding permanence and access.

HOW OFTEN SHOULD I CHECK MY SOLAR THERMAL BARREL?

It’s advisable to conduct assessments at least twice a year—before peak summer and winter seasons. Regular checks can help identify any insulation degradation, moisture intrusion, or heat loss issues. Furthermore, keeping an eye on the overall system ensures that any potential concerns are addressed early, preventing costly repairs in the future. Developing a routine monitoring schedule enhances investment protection while bolstering energy efficiency.

HOW DOES WEATHER AFFECT SOLAR THERMAL INSULATION BARRELS?

Solar thermal insulation barrels can be significantly influenced by environmental conditions. Extreme temperatures, both hot and cold, can lead to insulation degradation over time. Prolonged exposure to freezing temperatures without adequate blocking techniques can result in cracks or breaks in the barrel. Likewise, excessive heat can compromise the adhesive properties of sealants, leading to leaks. Awareness of local weather patterns assists in implementing appropriate preventative measures for maintaining optimal performance.

In summary, effectively blocking the pipe opening of a solar thermal insulation barrel requires a combination of suitable materials, methods, and ongoing maintenance practices. The initial steps involve understanding the barrel’s structural design and the methods needed to ensure solid sealing. From specially designed caps or plugs to waterproof sealants and welded fittings, numerous options exist to suit specific scenarios. It is equally essential to consider insulation materials surrounding the barrel and to implement robust maintenance routines to enhance efficiency. Regular inspections and cleaning help preserve the system’s integrity while promoting effective energy usage. Users must take advantage of seasonal strategies, optimizing the barrel’s setup for varying weather conditions. Overall, maintaining blocked pipe openings ultimately supports the longevity and efficiency of the solar thermal system, enabling users to reap the maximum benefits from their investment in sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-block-the-pipe-opening-of-solar-thermal-insulation-barrel-2/